On September 27, 2025, the 25th China International Industry Fair (CIIF) concluded successfully at the National Exhibition and Convention Center (Shanghai). This year’s fair attracted over 3,000 exhibitors from 28 countries and regions worldwide, welcomed 224,000 professional visitors, and achieved a total online exposure of over 2.3 billion—setting a new historical record.

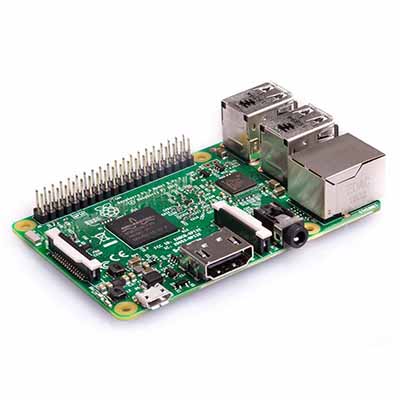

At this annual grand event of the industrial sector, EDATEC, together with Raspberry Pi and CODESYS, emerged as one of the most eye-catching highlights. The three parties jointly showcased industrial automation solutions based on the Raspberry Pi platform, covering a complete ecosystem from edge computing to motion control, and from smart PLCs to industrial HMIs. These solutions won high praise from numerous professional visitors and industry media.

Industrial Raspberry Pi "Goes Mainstream": From a "Maker Essential" to an "Industrial Tool"

At the joint booth of EDATEC and Raspberry Pi, visitors streamed in continuously—its average daily reception volume doubled compared to the previous fair, earning it the media nickname "the corner most like the morning rush hour in the subway." The exhibition not only attracted a large number of engineers, system integrators, and representatives from manufacturing enterprises but also received concentrated coverage from ten top industrial media outlets, including: Huicong Electronics Network, Electronic Engineering World (EEWorld), Eefocus, Elecfans, China Electronics Network, DriveNet, Digital Business Times, Geek Network, Electronic Engineering Album, and Electronic Products World.

Beyond industrial media, the fair also drew interviews from well-known Bilibili content creators (UPs), such as Tongji Zihao Xiong, Daerwen, Engineer Teacher Sun, and Wang Mingdong.

Media attention focused on five core keywords: stability, open-source, cost reduction, community, and iteration speed. The Marketing Director of EDATEC stated: "The industrialization of Raspberry Pi is not about replacing traditional PLCs; it is about providing engineers with a new 'out-of-the-box' option, shortening the time from prototype to mass production from months to weeks."

Empowered by CODESYS: Building an Industrial-Grade Real-Time Control Platform

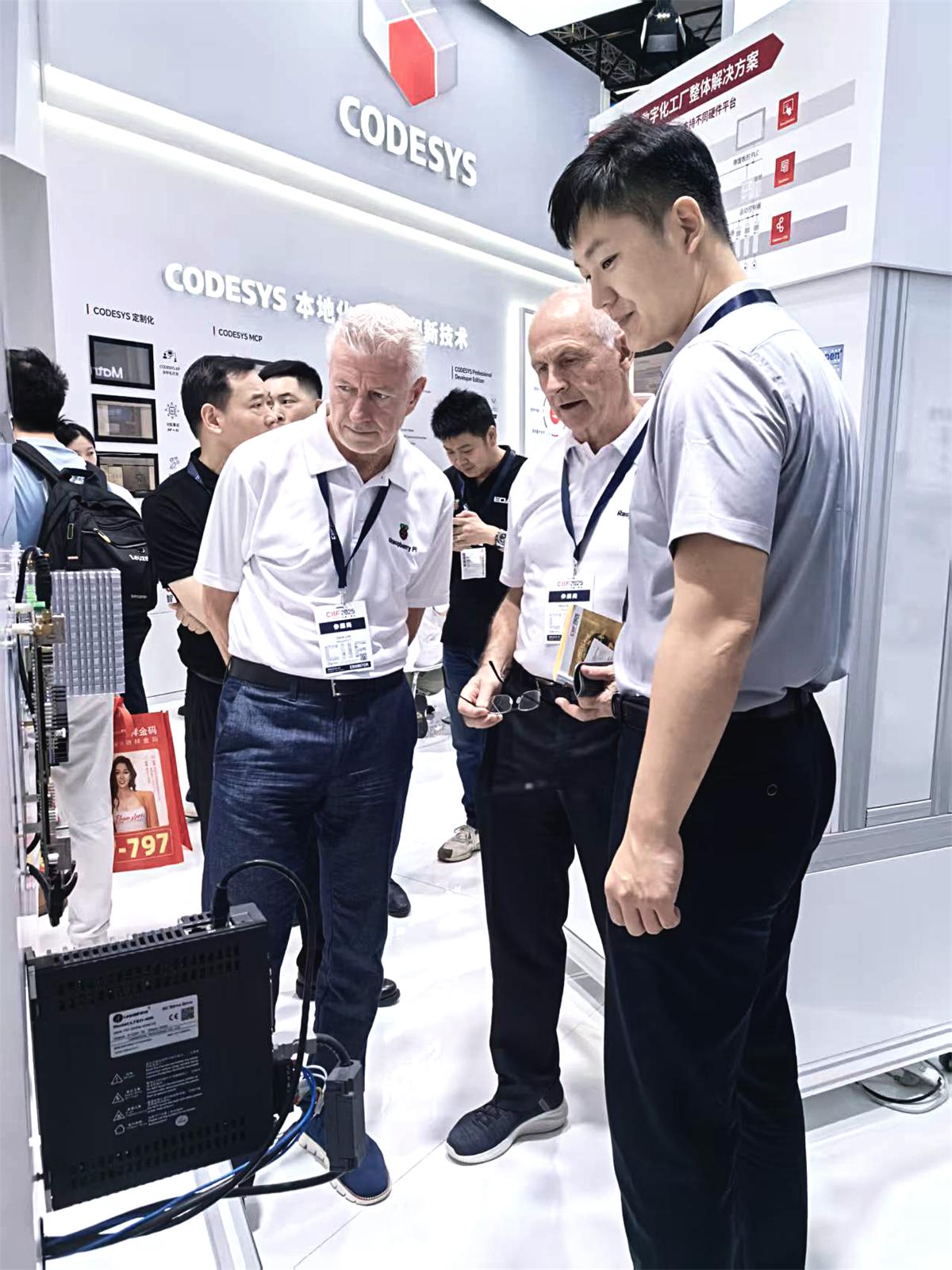

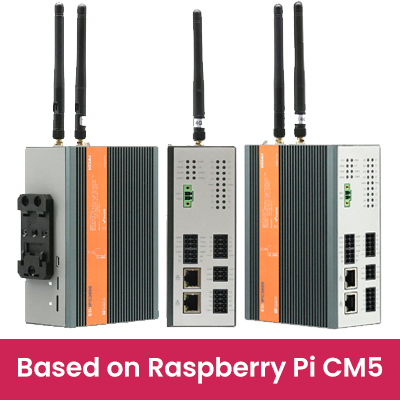

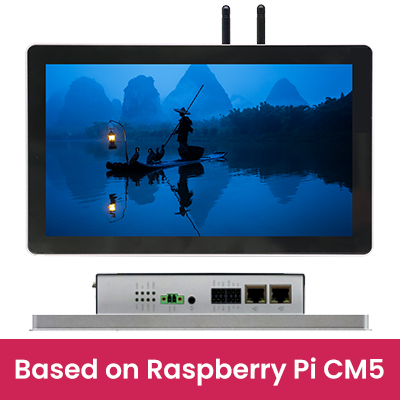

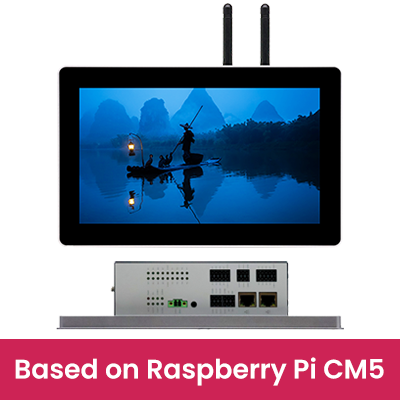

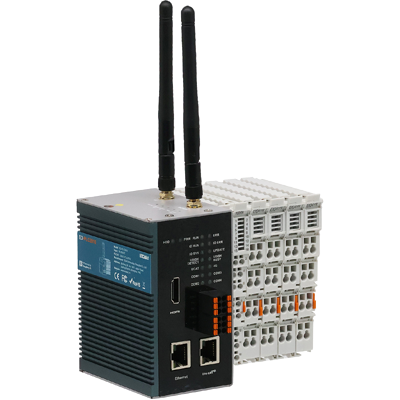

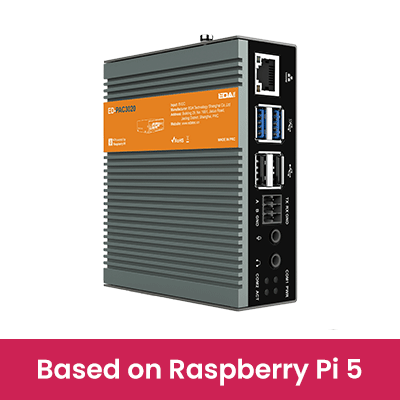

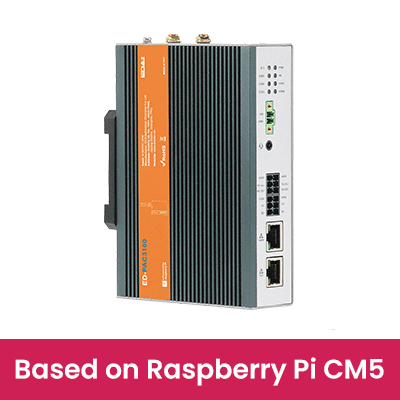

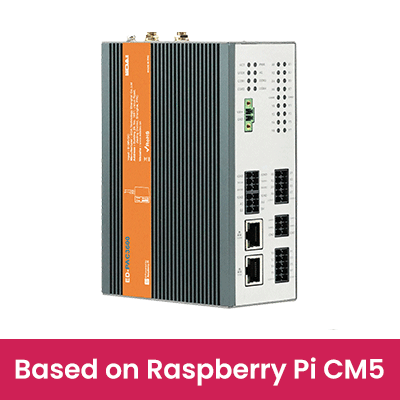

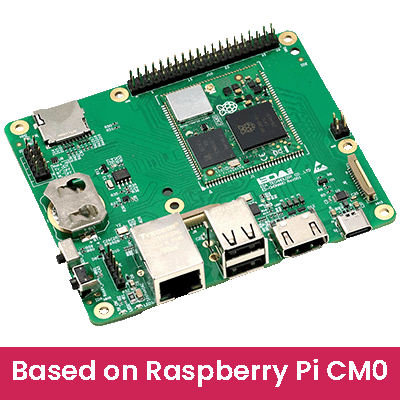

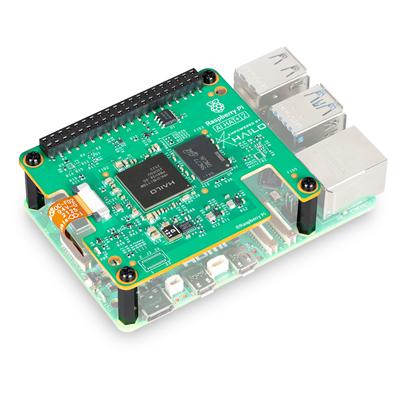

One of the technical highlights of this fair was the industrial-grade real-time control system jointly launched by EDATEC, Raspberry Pi, and CODESYS. With the Raspberry Pi CM5 as its core controller, the system integrates CODESYS Runtime and EtherCAT bus technology, achieving a 1ms bus cycle and jitter of less than 50 microseconds—meeting the high-precision synchronous control needs of industrial robots, 3D printing, CNC machines, and other equipment.

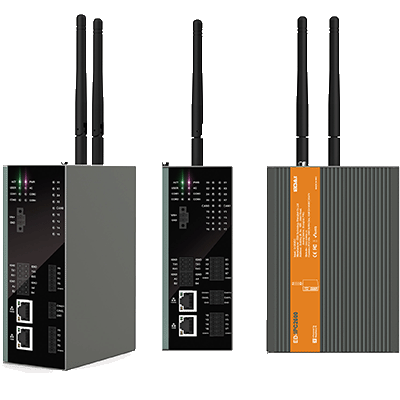

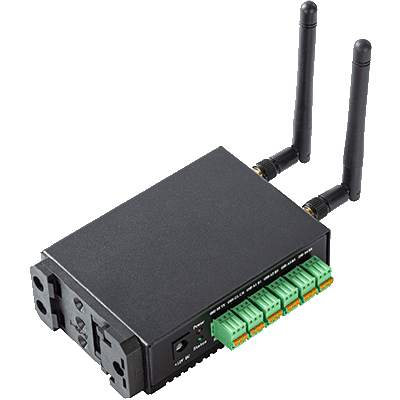

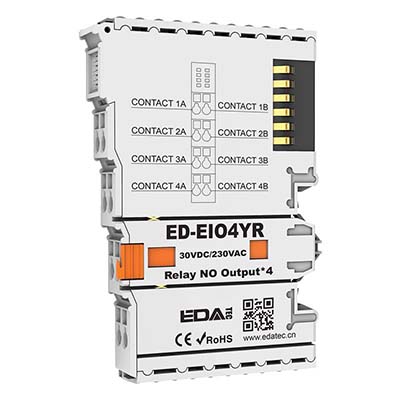

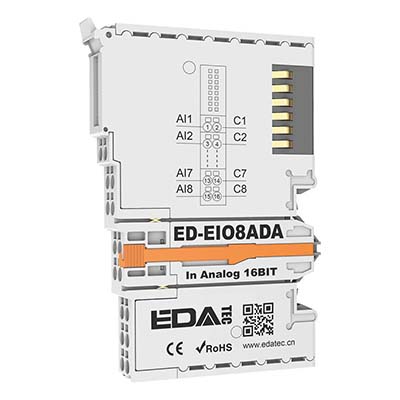

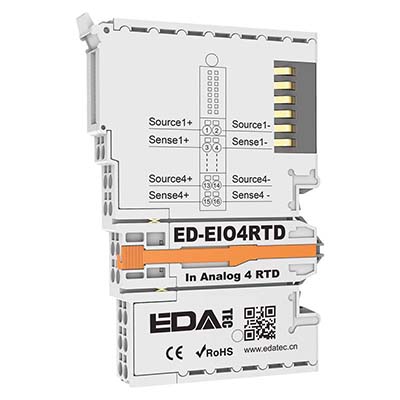

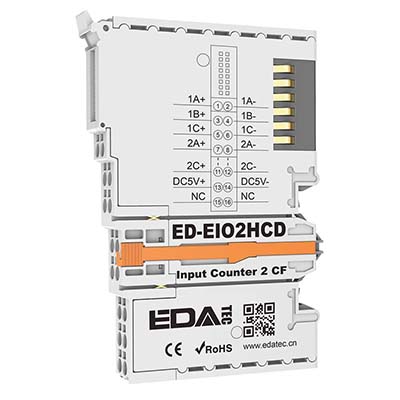

In addition, the smart PLC system based on the CM4 was also on display. It supports 32 types of I/O modules, Modbus TCP/IP, and EtherCAT protocols, and is equipped with a 10.1-inch HMI (Human-Machine Interface). This system provides standardized and modular solutions for factory automation and process control.

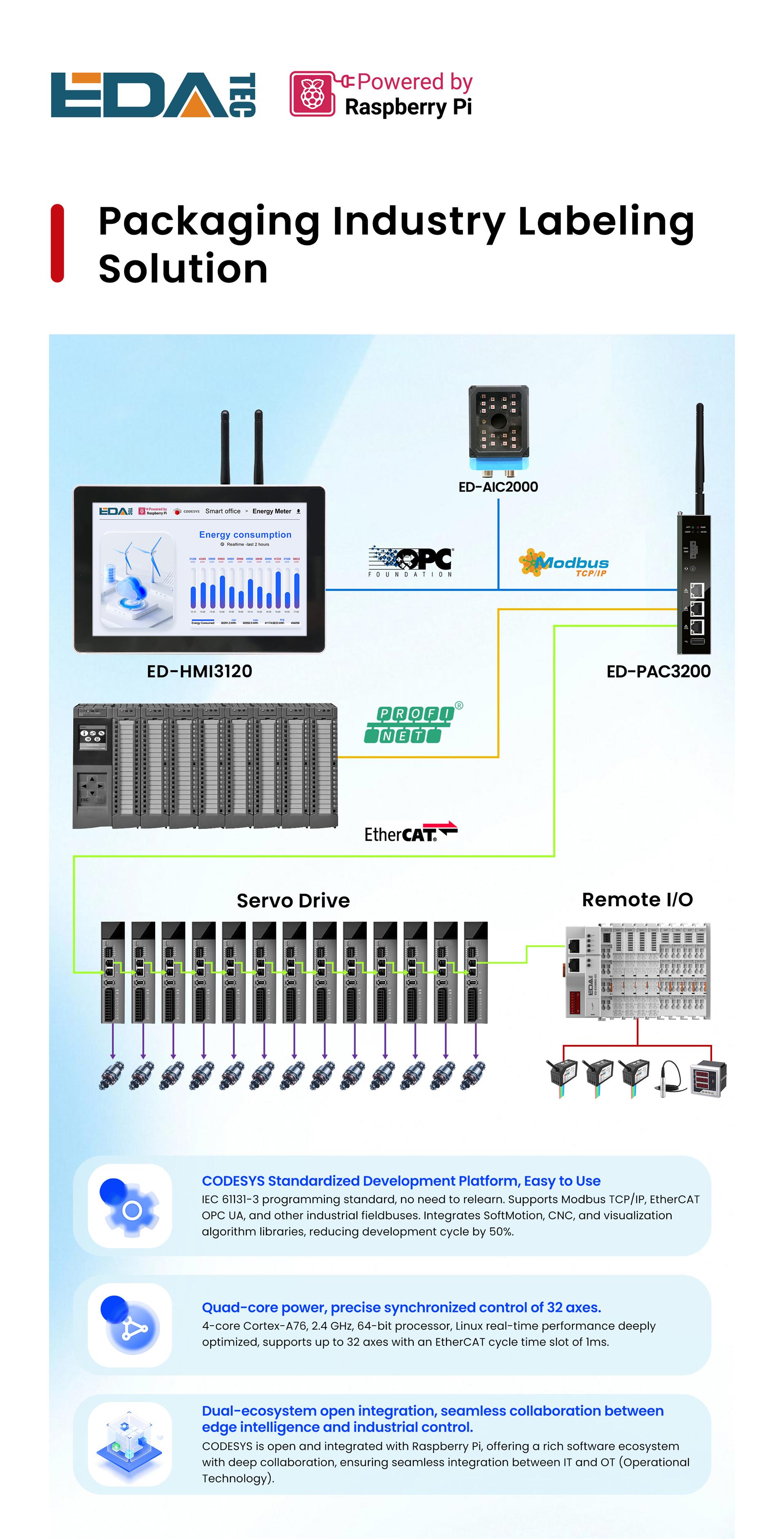

Addressing Packaging Industry Needs: A Competitive Labeling Solution

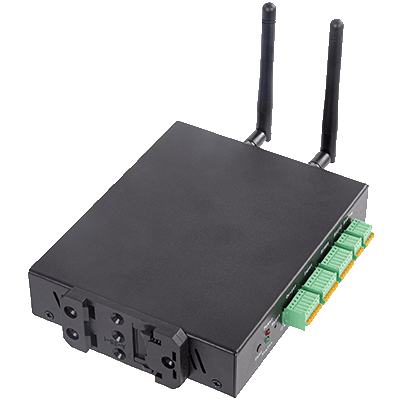

Amid the wave of industrial automation, the packaging industry has an increasingly urgent demand for efficient and accurate labeling solutions. Leveraging the Raspberry Pi platform, EDATEC has launched a highly competitive labeling solution for the packaging industry, injecting new vitality into the sector’s intelligent upgrading.

System Architecture: Synergistic Collaboration of Components

The solution consists of a variety of key hardware and technical architectures, forming an integrated whole:

- HMI & Control Core: The ED-HMI3120 serves as the human-machine interface, intuitively displaying data such as energy consumption to facilitate monitoring and operation by staff. The ED-PAC3200 acts as the core controller, coordinating the orderly operation of all hardware components.

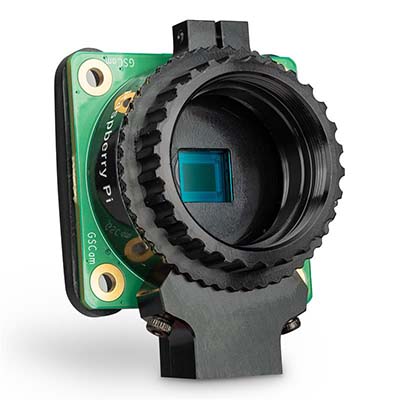

- Visual Inspection Unit: The ED-AIC2000 is responsible for visual inspection, accurately identifying visual information related to packages and labels to ensure labeling accuracy.

- Drive & Expansion Modules: Multiple Servo Drives provide power for actions like labeling, enabling precise mechanical motion control. Remote I/O modules expand the system’s interface capabilities, facilitating connections to various peripheral devices. Meanwhile, the system supports industrial communication protocols such as OPC, Modbus TCP/IP, PROFINET, and EtherCAT, ensuring efficient and stable data transmission between components.

Technical Advantages: Empowering Efficient Development & Precise Control

- User-Friendly Development Platform: Based on the standardized CODESYS development platform and adhering to the IEC 61131-3 programming standard, engineers do not need to learn a new programming system. The platform also integrates SoftMotion, CNC, and visualization algorithm libraries, reducing the development cycle by 50% and significantly improving development efficiency.

- Powerful Computing & Control Capabilities: Equipped with a quad-core Cortex-A75 processor running at 2.4GHz, the system features in-depth optimization of Linux real-time performance. With the EtherCAT protocol, it can achieve precise synchronous control of 32 axes, and the EtherCAT cycle time slot is only 1ms—meeting the high-speed and high-precision control requirements of the labeling process.

- Open Ecosystem Integration: CODESYS and Raspberry Pi have realized open integration, boasting a rich software ecosystem. This integration ensures in-depth collaboration between IT (Information Technology) and OT (Operational Technology), enabling seamless coordination between edge intelligence and industrial control, and bringing smarter and more flexible application experiences to the packaging and labeling process.

Conclusion

While the 2025 Shanghai Industry Fair has come to an end, the blueprint for smart industry has only just begun to unfold. EDATEC, together with Raspberry Pi and CODESYS, is injecting new innovative momentum into the global manufacturing industry through an open, flexible, and efficient industrial edge computing platform. In the future, with the implementation of more industrial scenarios, this "iron triangle" partnership is expected to lead smart industry into a new phase of greater openness, collaboration, and sustainable development.

En

En