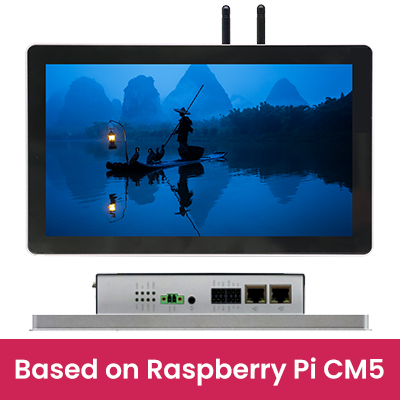

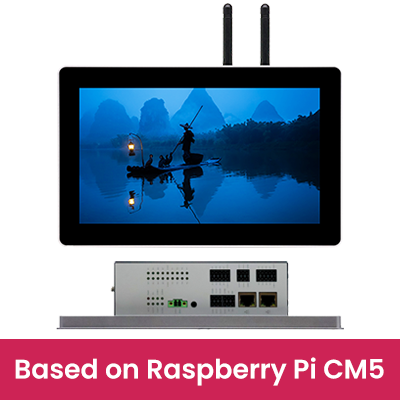

Model No. | LCD Size | Resolution | Aspect ratio | # of Colors | Luminance | Viewing Angle | Multi-touch | Dimensions | Weight |

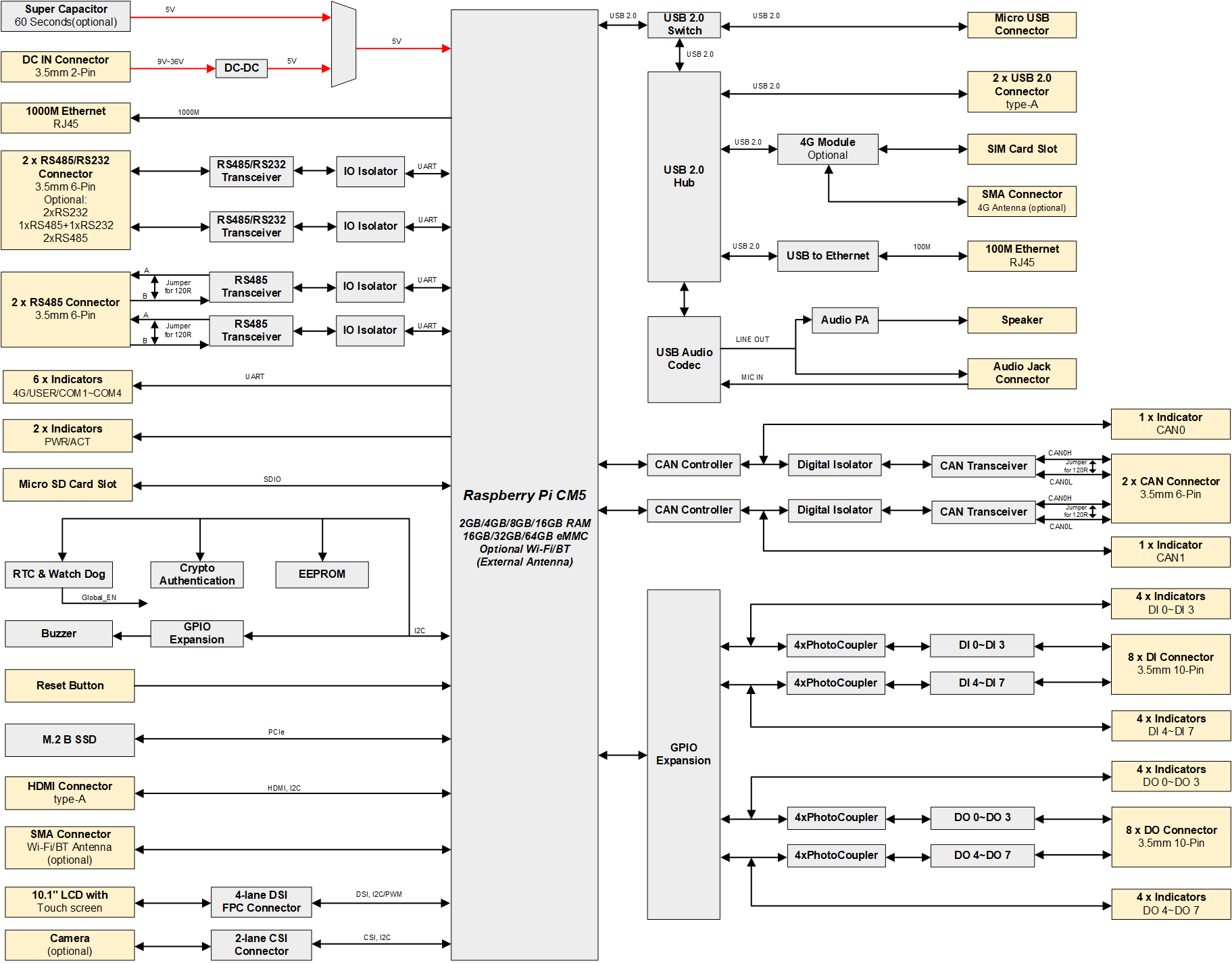

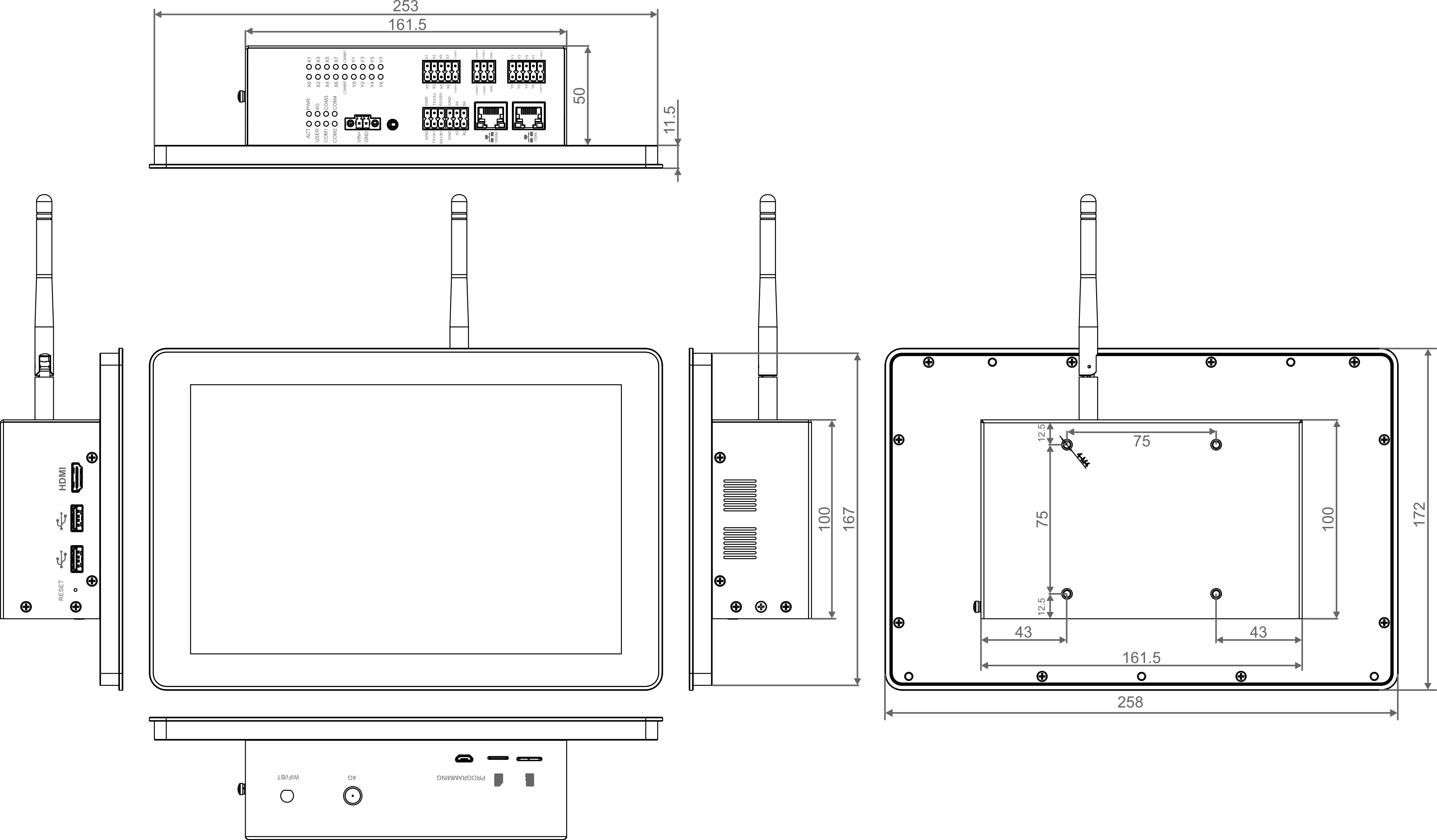

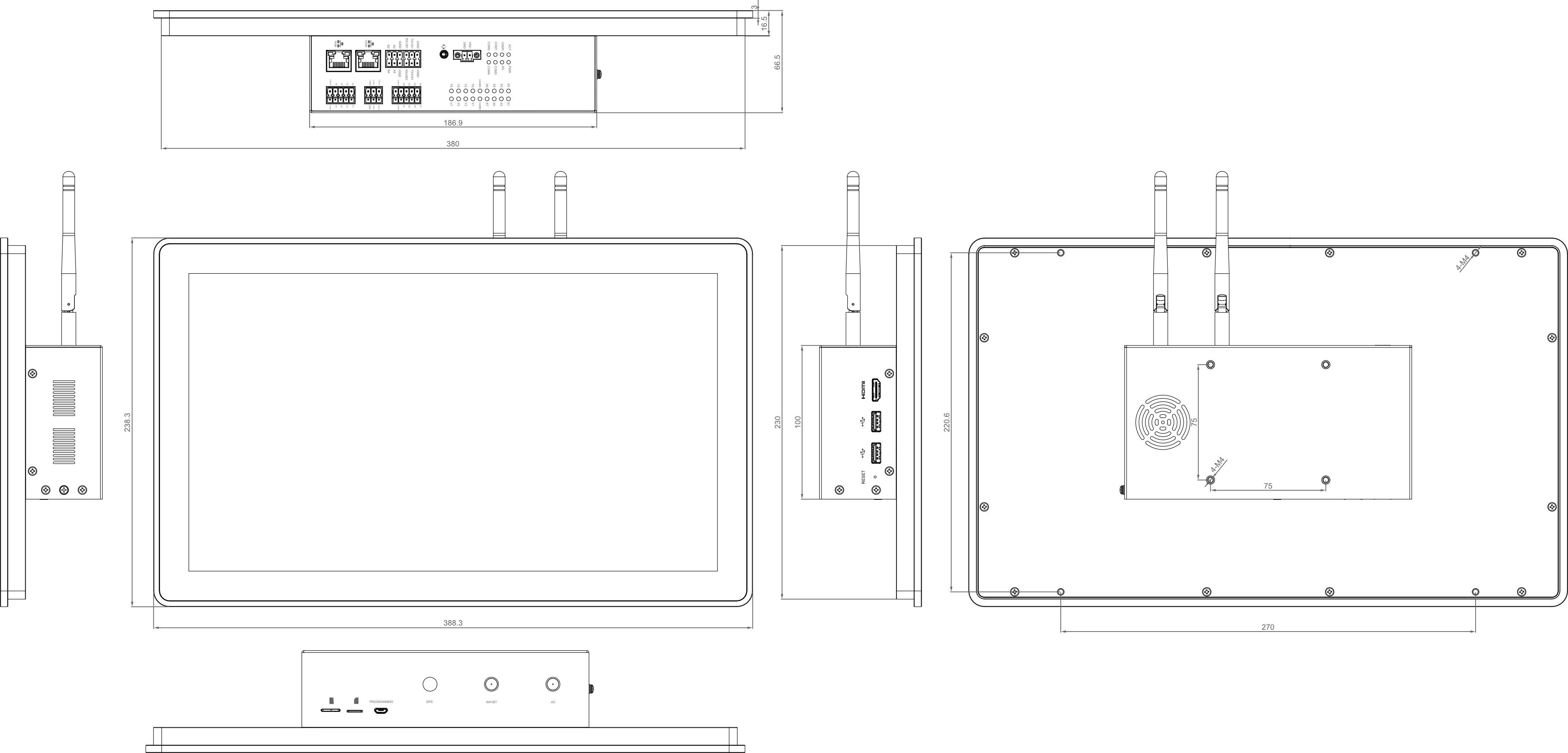

HMI3630-101C | 10.1" | 1280 x 800 | 16:10 | 16.7M | 400 | 160°/160° | 10 | 258 x 172 x 61.5 | About 1300g |

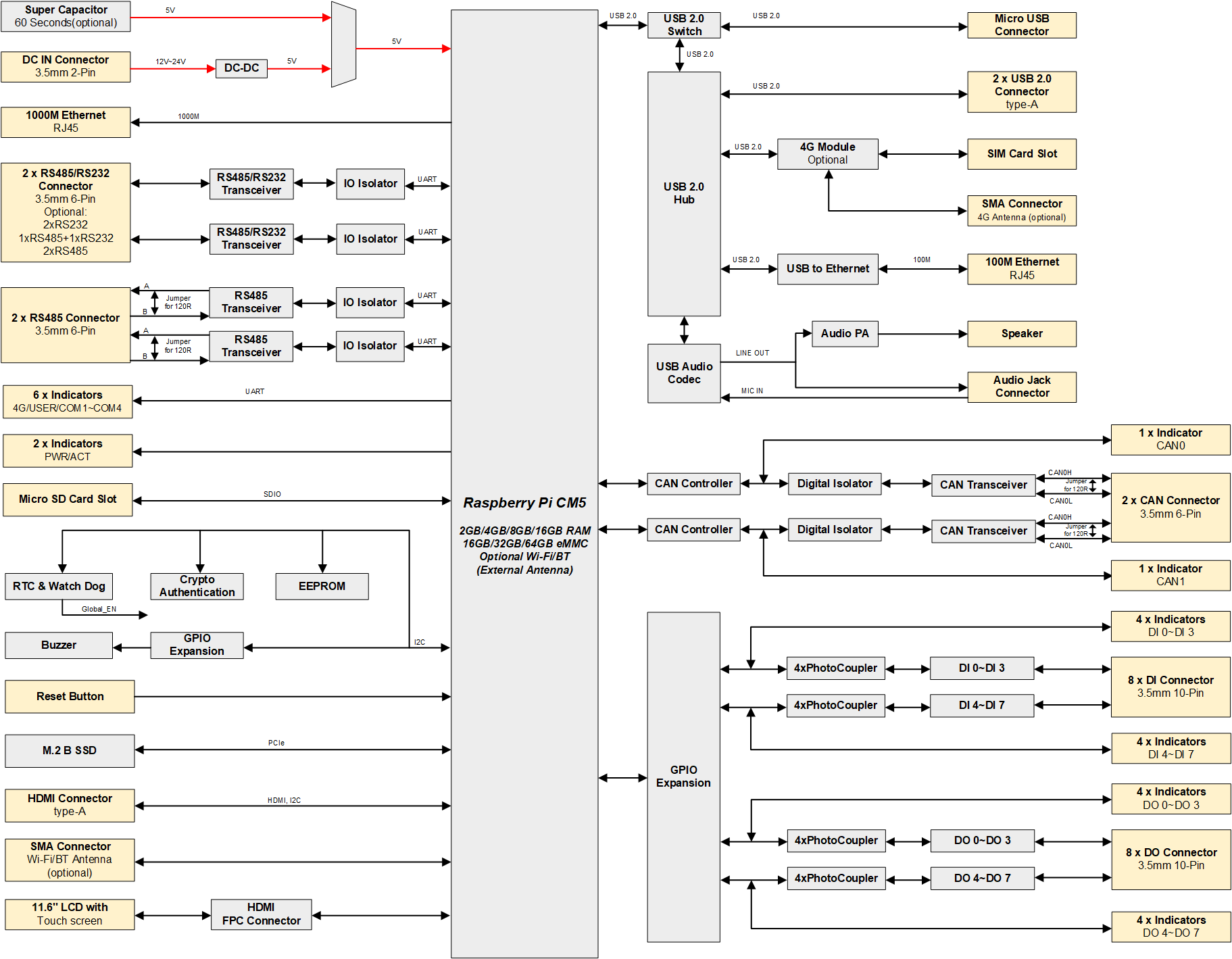

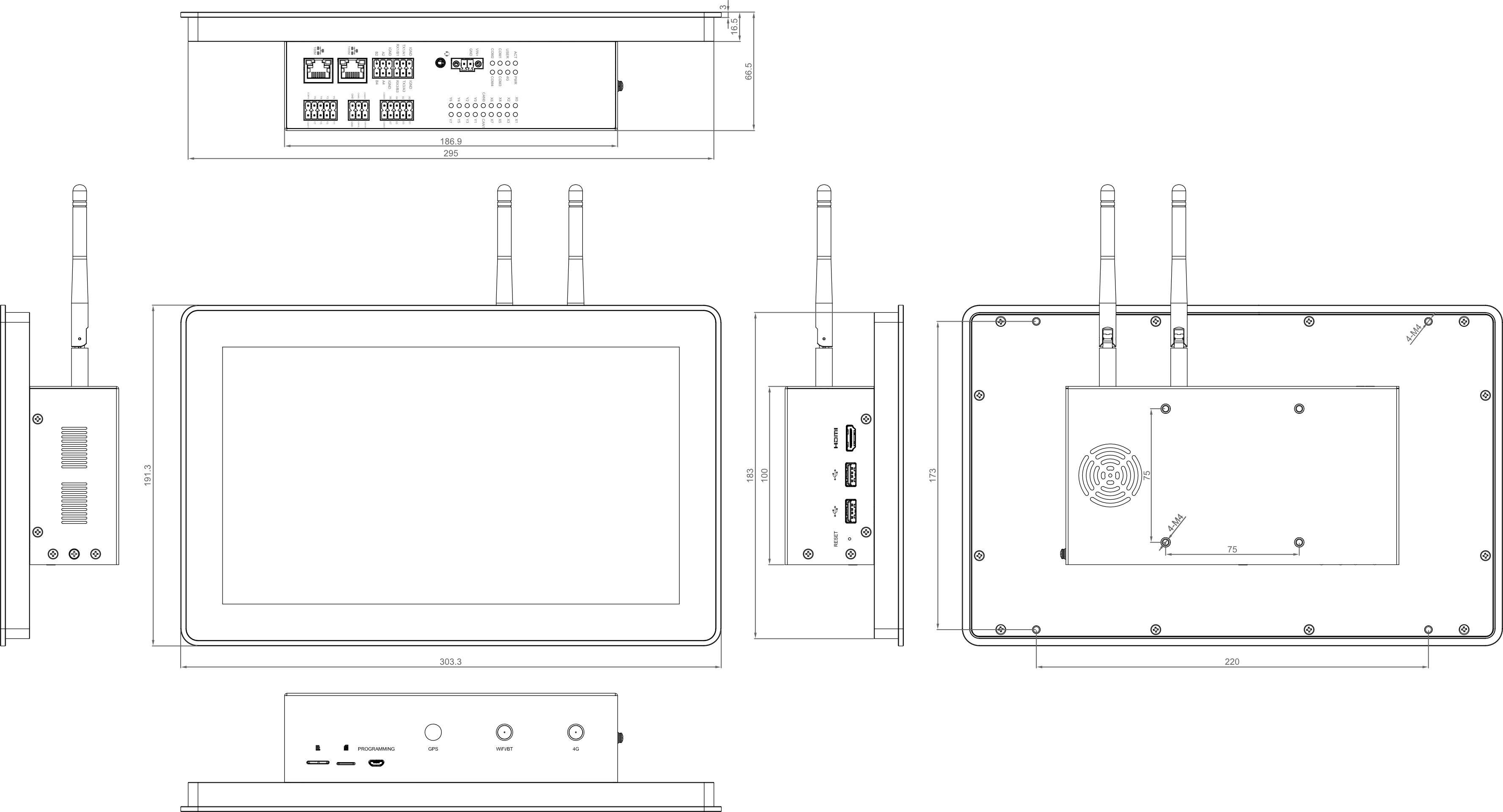

HMI3630-116C | 11.6" | 1920 x 1080 | 16:9 | 16.7M | 450 | 170°/170° | 5 | 305 x 193 x 66.5 | About 2000g |

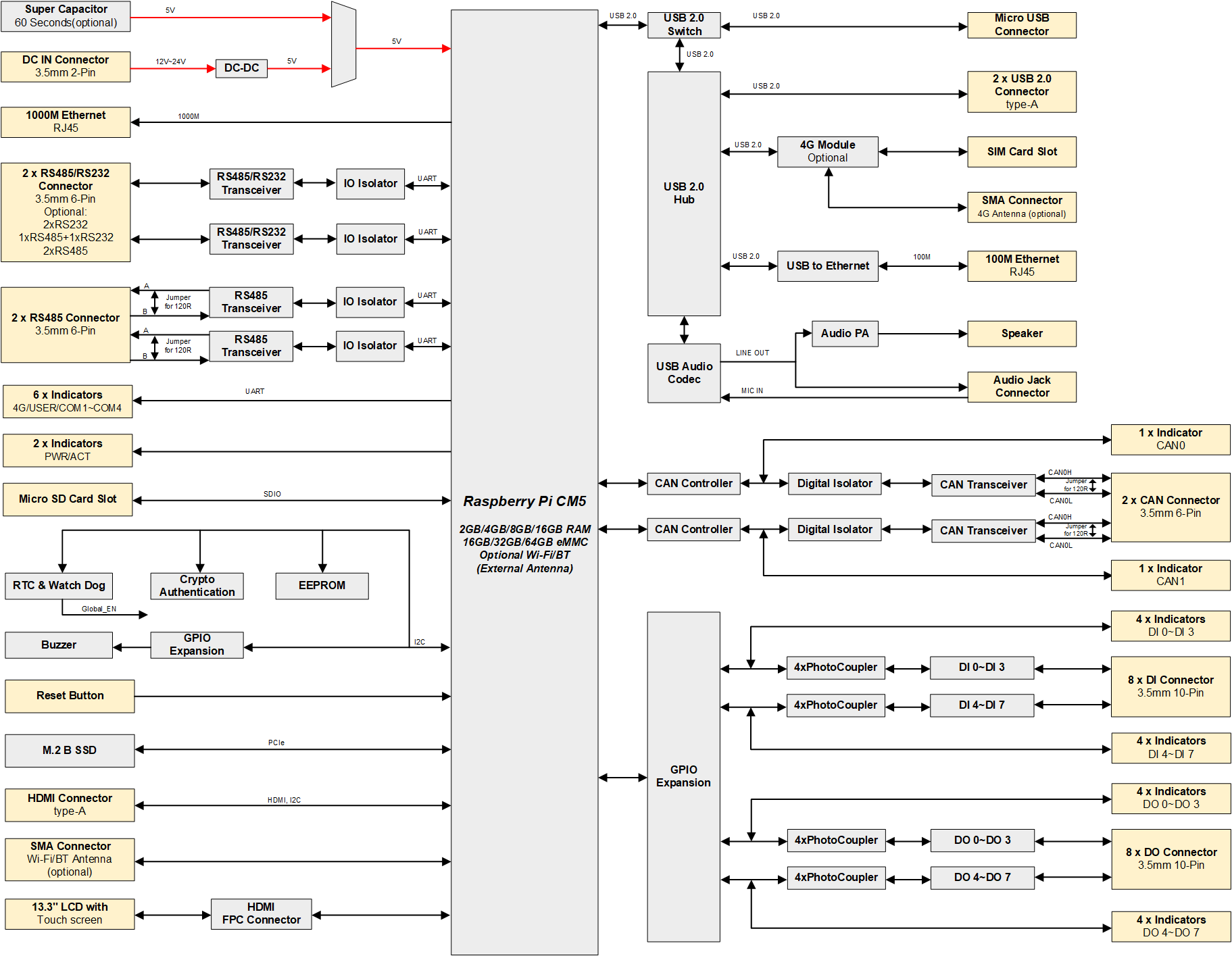

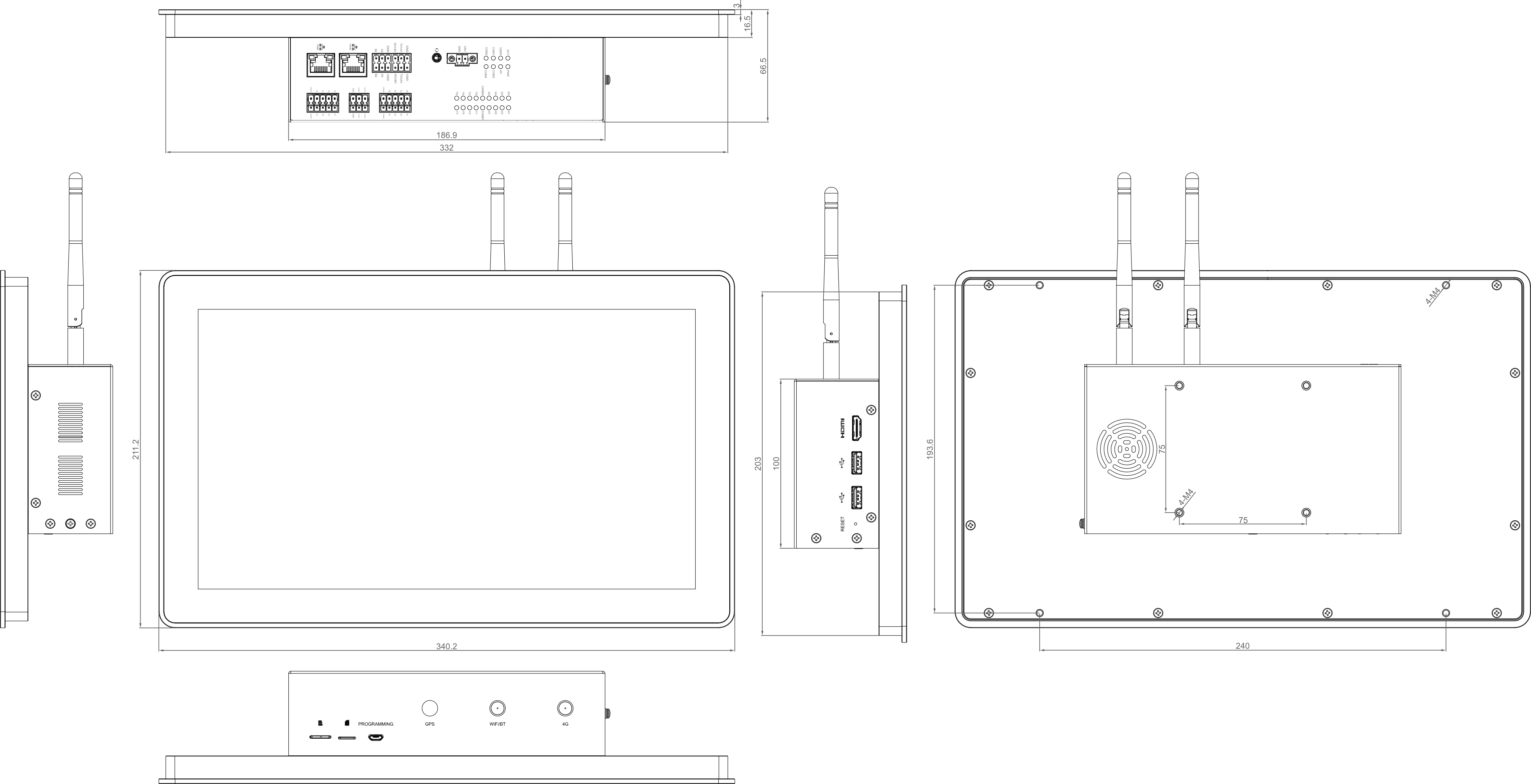

HMI3630-133C | 13.3" | 1920 x 1080 | 16:9 | 16.7M | 450 | 160°/160° | 5 | 340.2 x 211.2 x 66.5 | About 2200g |

HMI3630-156C | 15.6" | 1920 x 1080 | 16:9 | 16.7M | 450 | 170°/170° | 5 | 388.3 x 238.3 x 66.5 | About 2600g |

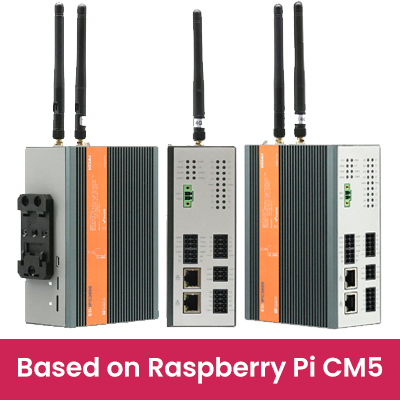

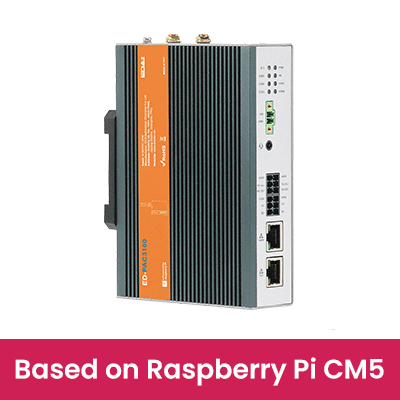

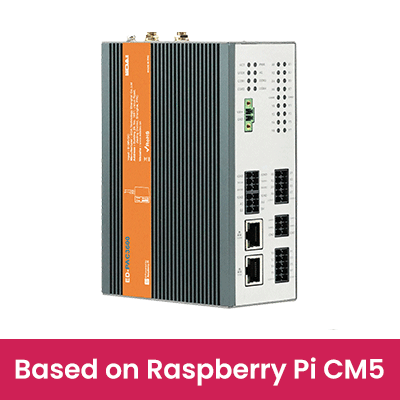

Product Positioning

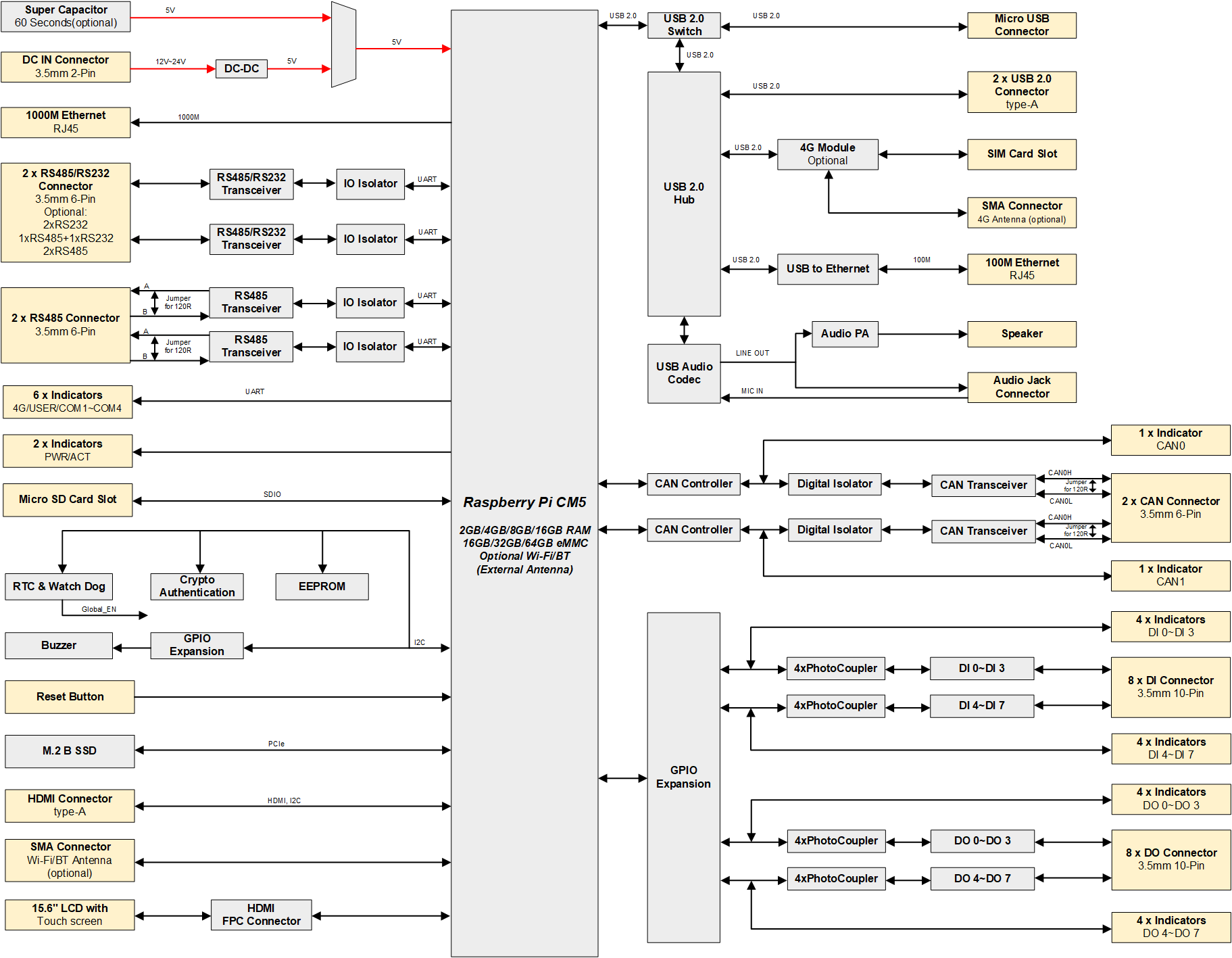

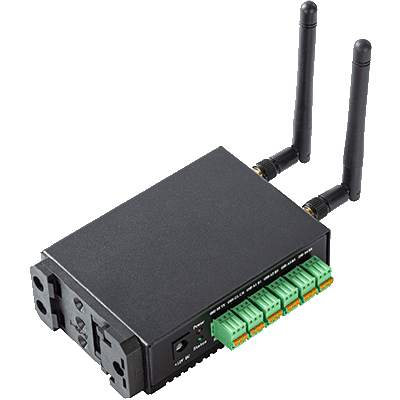

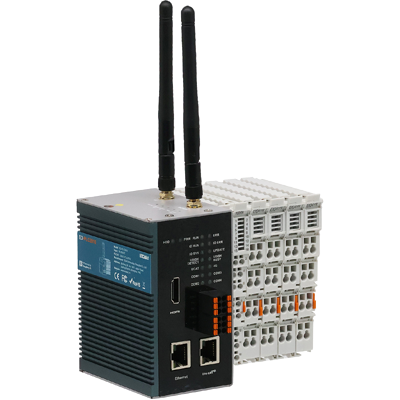

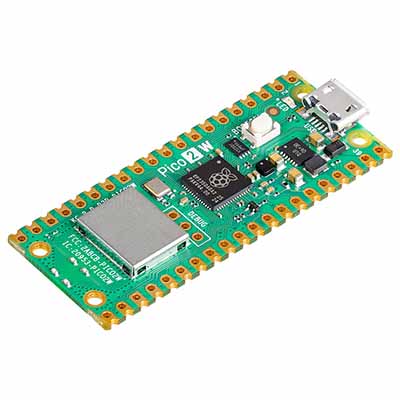

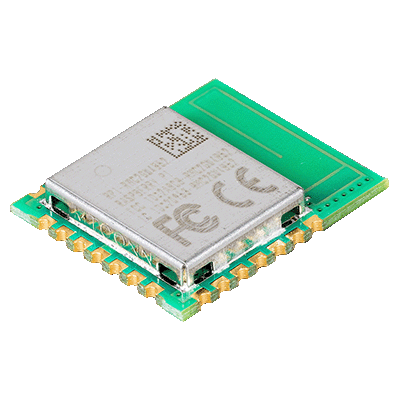

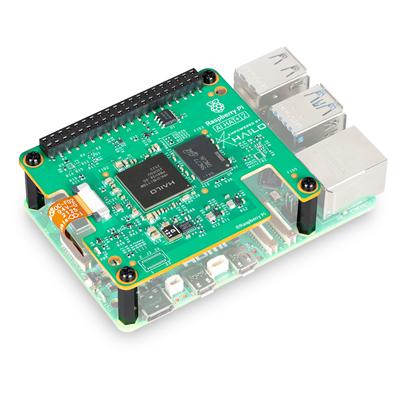

A high-density industrial control terminal designed for mission-critical automation and complex bus communication scenarios. Built on Raspberry Pi CM5 architecture, it integrates 8 isolated DI/DO, 2 CAN buses, and 4 isolated serial ports, delivering all-protocol connectivity and scalability for smart manufacturing, transportation control, and energy management applications.

xplore in-depth reviews and coverage of ED-HMI3630 Series by leading international media outlets! Click the links to learn more:

Core Advantages

Module | Highlights | Key Specifications/Technologies |

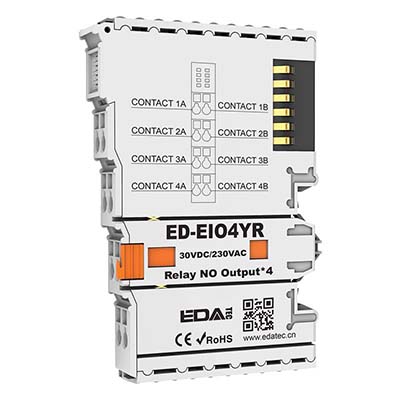

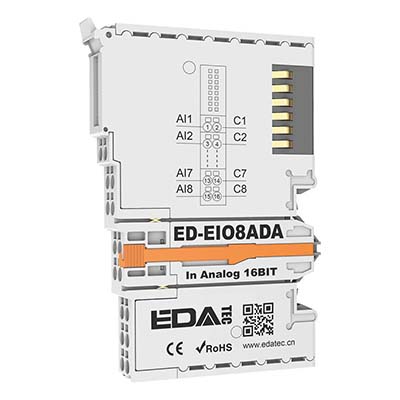

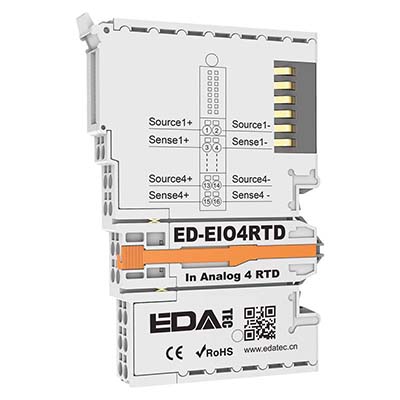

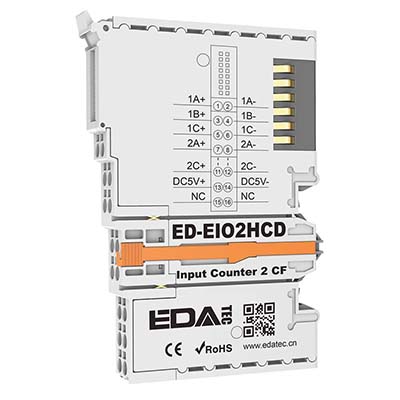

Ultra-High-Density I/O | Direct connectivity for industrial devices | - 8× Isolated DI/DO (5KV isolation, NPN/PNP/dry contact) |

High-Performance Compute | Real-time control and edge analytics | - Quad-core Cortex-A76@2.4GHz (BCM2712) |

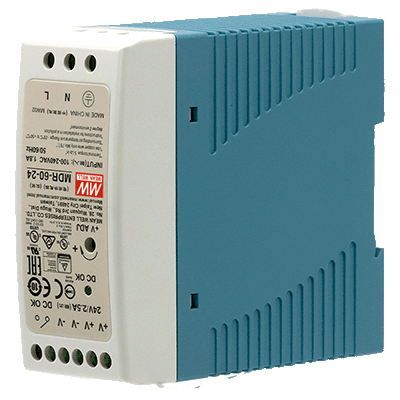

Industrial Toughness | Built for extreme environments | - 9-36V DC Input (reverse polarity/overload protection) |

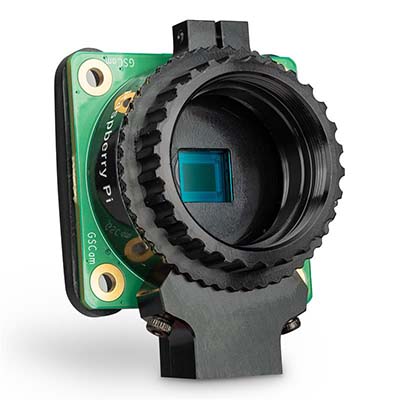

Sunlight-Ready Display | Glare-resistant operation under harsh lighting | - 10.1" TFT (1280×800, 400cd/m²) |

Flexible Control Ecosystem | Open architecture for diverse automation needs | - Optional CODESYS Integration (soft PLC cycle ≤1ms) |

Differentiation

✅ Ultra-High-Density Industrial I/O: 8 DI/DO + 2 CAN + 4 serial ports directly connect PLCs, sensors, and actuators – reduce expansion module costs by 80%.

✅ Smart Power Resilience: 9-36V DC input range handles unstable grids with reverse-polarity/overload safeguards.

✅ Dual-Network Zero Interference: Physically isolated 1Gbps (control) + 100Mbps (data) networks ensure millisecond-level response.

✅ Dual-Control Flexibility: Optional CODESYS for PLC-grade logic or custom Linux-based solutions – seamlessly modernize legacy systems.

Typical Applications

🏭 Automotive Production Control: Monitor stamping machines via 8 DI, synchronize welding robots via CAN, and run CODESYS multi-station logic.

🚦 Smart Traffic Management Hub: CAN buses control traffic lights; 4 x RS485 ports collect vehicle flow data for edge-optimized routing.

⚡ Substation Monitoring Panel: Remotely toggle breakers via 8 DO, maintenance log data on M.2 SSD.

📦 Port AGV Command Center: Direct AGV fleets via Wi-Fi 5, extend surveillance to HDMI monitors, deploy rapidly with VESA mounts.

HS CODE

| HS CODE | COO |

| 8471504001 | CN |

En

En