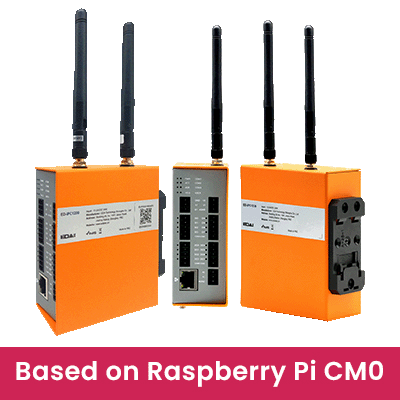

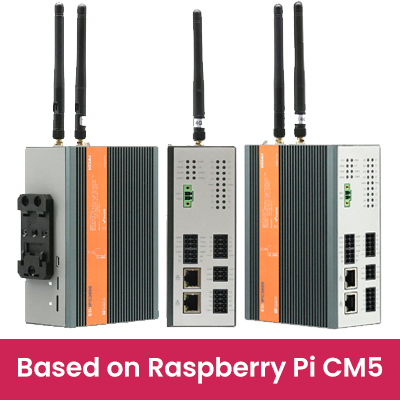

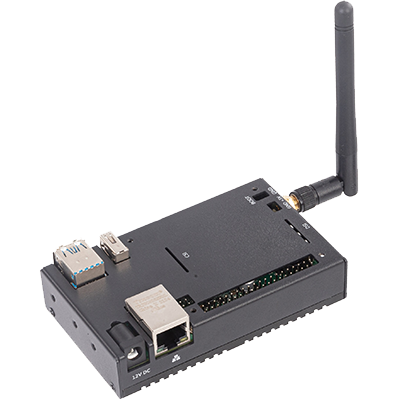

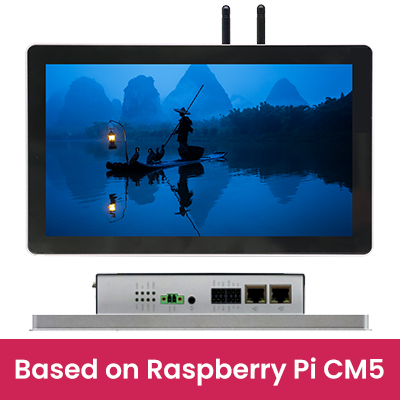

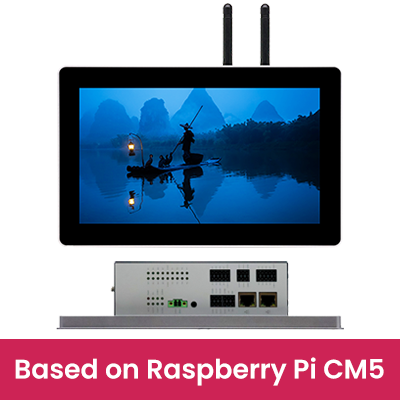

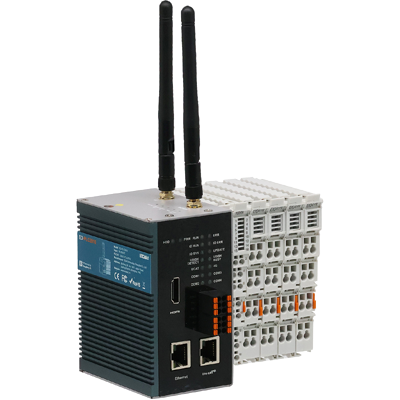

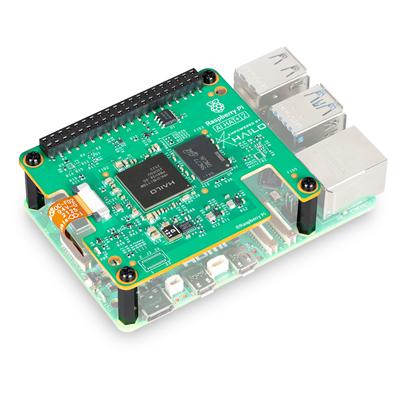

ED-PLC2010 delivers control, connectivity, and scalability in one platform – the open architecture solution for smart manufacturing’s toughest challenges.

Explore in-depth reviews and coverage of ED-PLC2010 by leading international media outlets! Click the links to learn more:

CNX Software LinuxGizmos Raspberry ME

Core Advantages

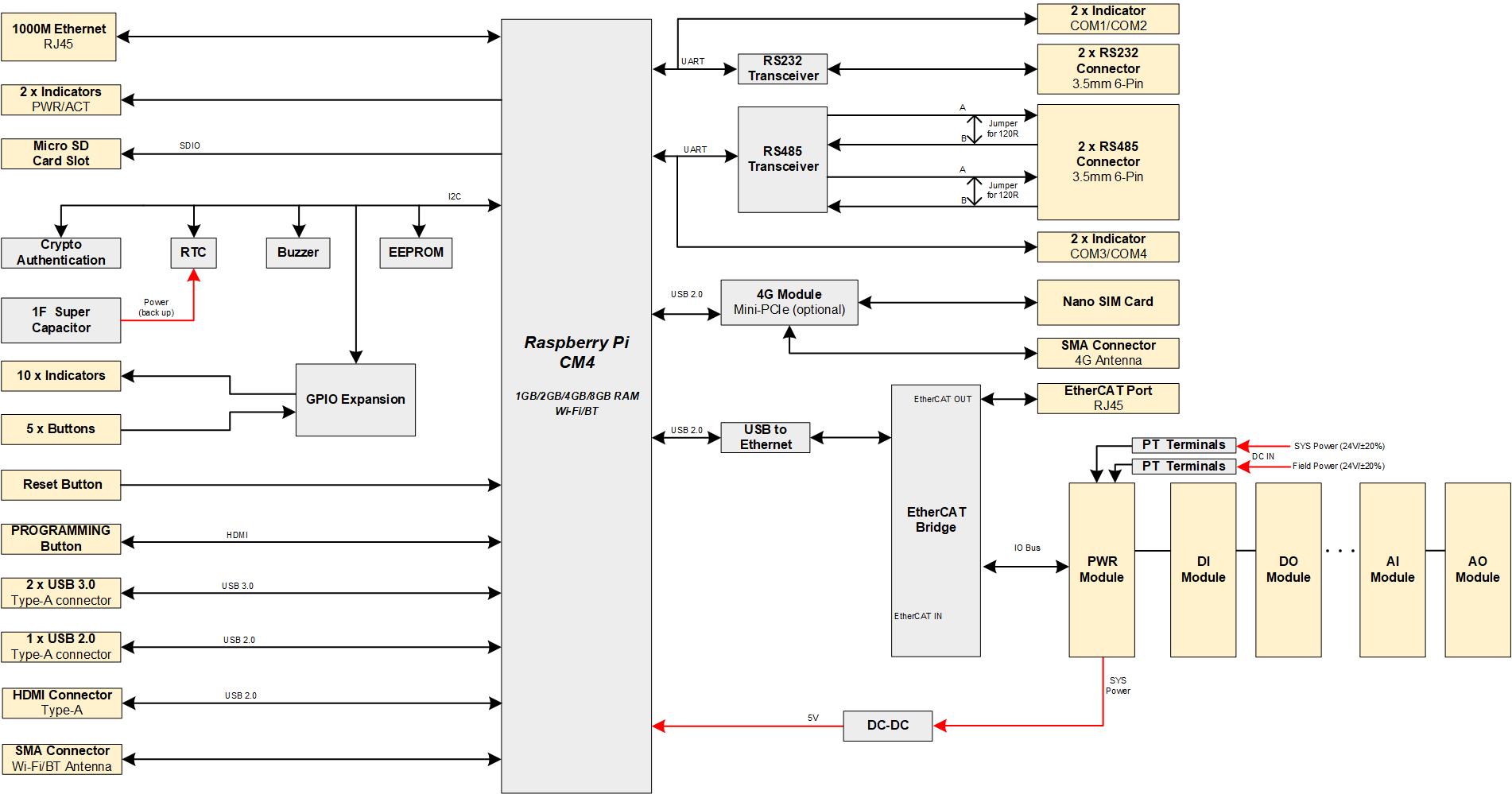

| Module | Highlights | Key Specifications/Technologies |

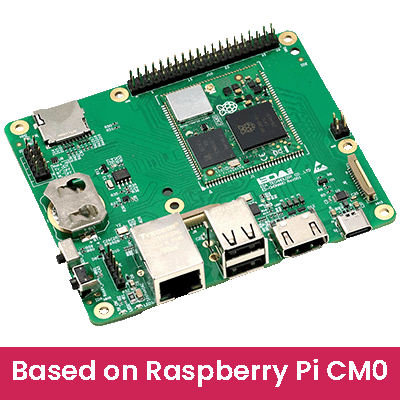

| High-Performance Computing | Multi-core power for advanced logic and edge analytics | - Quad-core Cortex-A72@1.5GHz (Broadcom BCM2711) - 8GB LPDDR4 RAM + 32GB eMMC - Micro SD expansion for user data storage |

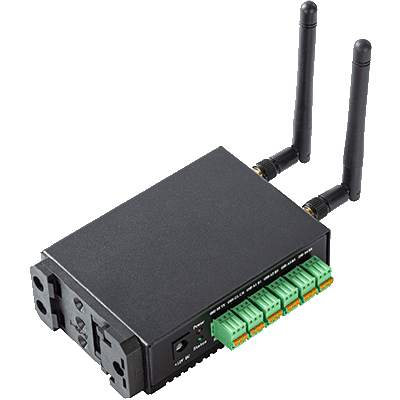

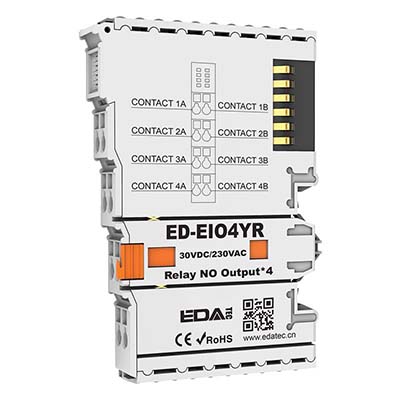

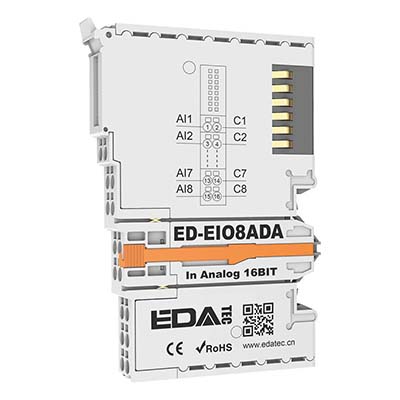

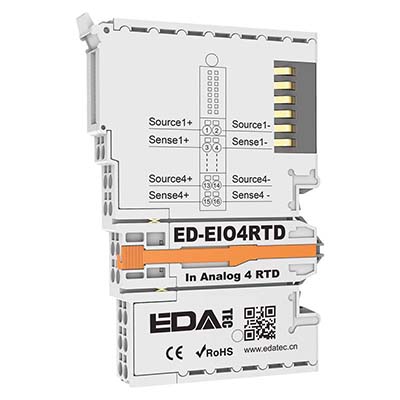

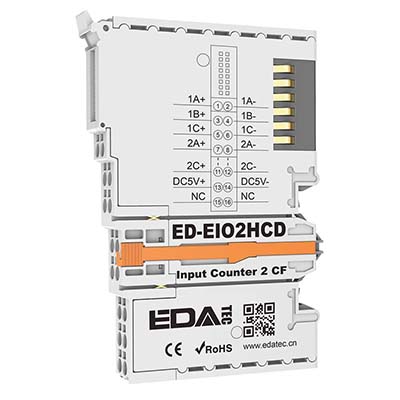

| Modular I/O Scalability | Tailor I/O configurations to diverse industrial needs | - Up to 32 I/O modules (DI/DO/AI/AO/RTD/TC/high-speed counter) - Tool-free hot-swappable design for field maintenance |

| Industrial Protocol Hub | Seamless OT/IT convergence | - Native EtherCAT Master (128 slaves max) - Modbus TCP Master (63 slaves max) - OPC UA Server + MQTT bidirectional gateway |

| Deterministic Control | CODESYS-driven precision for mission-critical automation | - CODESYS Control Runtime (Single/Multicore) - IEC 61131-3 programming (ST/LD/FBD/SFC/CFC) - SoftMotion/CNC+Robotics add-ons |

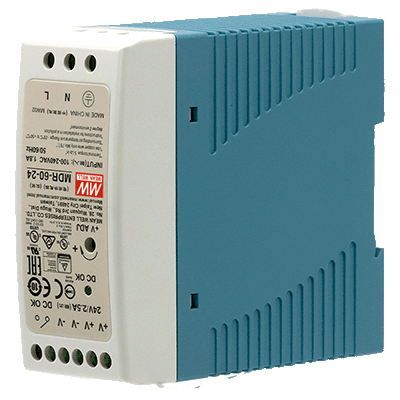

| Industrial Toughness | Built for 24/7 operation in harsh conditions | - -10°C~55°C operating range - 24V DC input (±20% tolerance) - Supercapacitor backup (critical process protection) - EMI-shielded metal housing |

Differentiation

✅ Unmatched I/O Flexibility: 32 modular I/O slots support 90% of industrial sensors/actuators (DI/DO/AI/AO/RTD/TC).

✅ Plug-and-Play Protocols: EtherCAT & Modbus TCP Master pre-integrated – zero-configuration deployment.

✅ Dual-Visualization Tools: CODESYS TargetVisu (local HMI) + WebVisu (remote monitoring) slash HMI development costs.

✅ Extended Thermal Tolerance: -10°C~55°C range outperforms standard PLCs (typically 0°C~50°C).

Typical Applications

🏭 Smart Production Line Control: Synchronize 8-axis EtherCAT drives while aggregating sensor data via Modbus TCP to MES.

⚡ Energy Management Gateway: Acquire grid metrics via AI/AO modules, push to cloud EMS via MQTT.

📡 Discrete Manufacturing Hub: Gigabit Ethernet for AGV control + RS485 legacy device integration + 4G cloud backhaul.

🔧 Predictive Maintenance Node: RTD/TC modules monitor bearing temps; AI modules analyze vibration for lifespan prediction.

En

En