Product Positioning

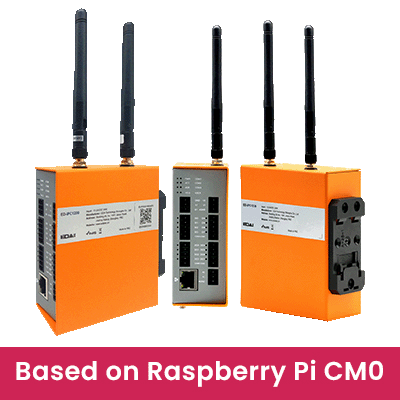

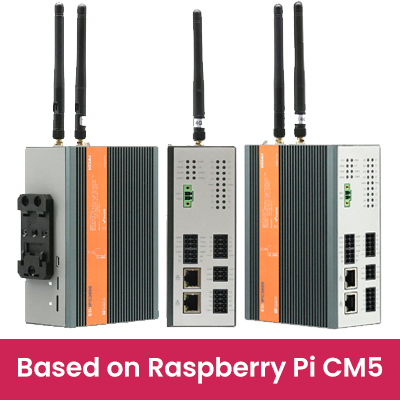

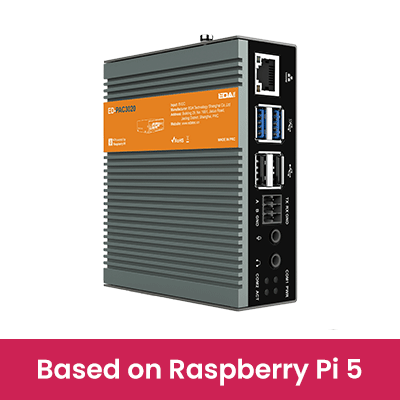

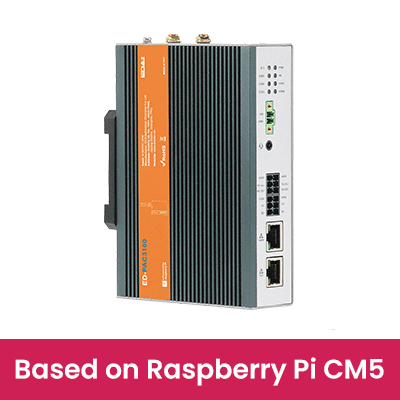

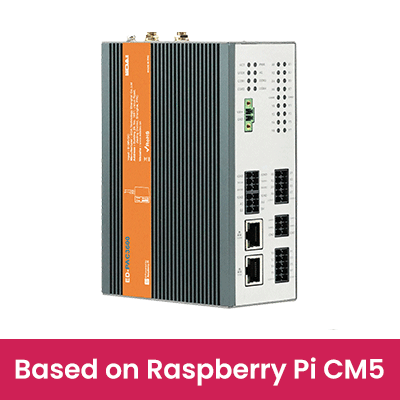

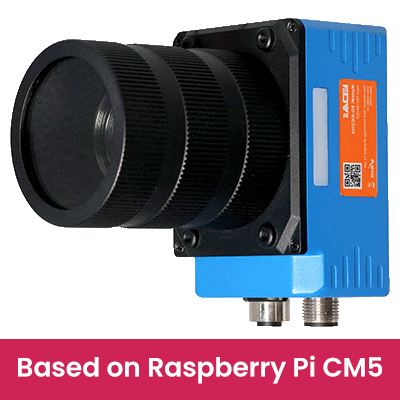

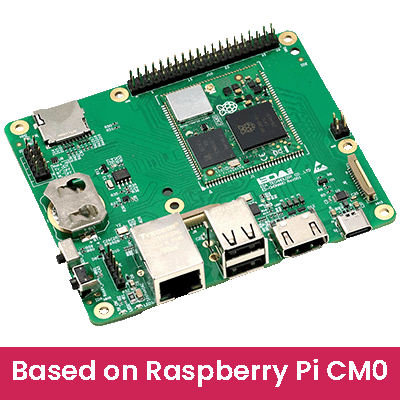

A high-precision motion controller for industrial automation, built on Raspberry Pi hardware with CODESYS real-time soft PLC core. Designed for microsecond-level response and multi-axis synchronization, it meets the stringent real-time demands of smart manufacturing, equipment networking, and mission-critical industrial environments.

Core Advantages

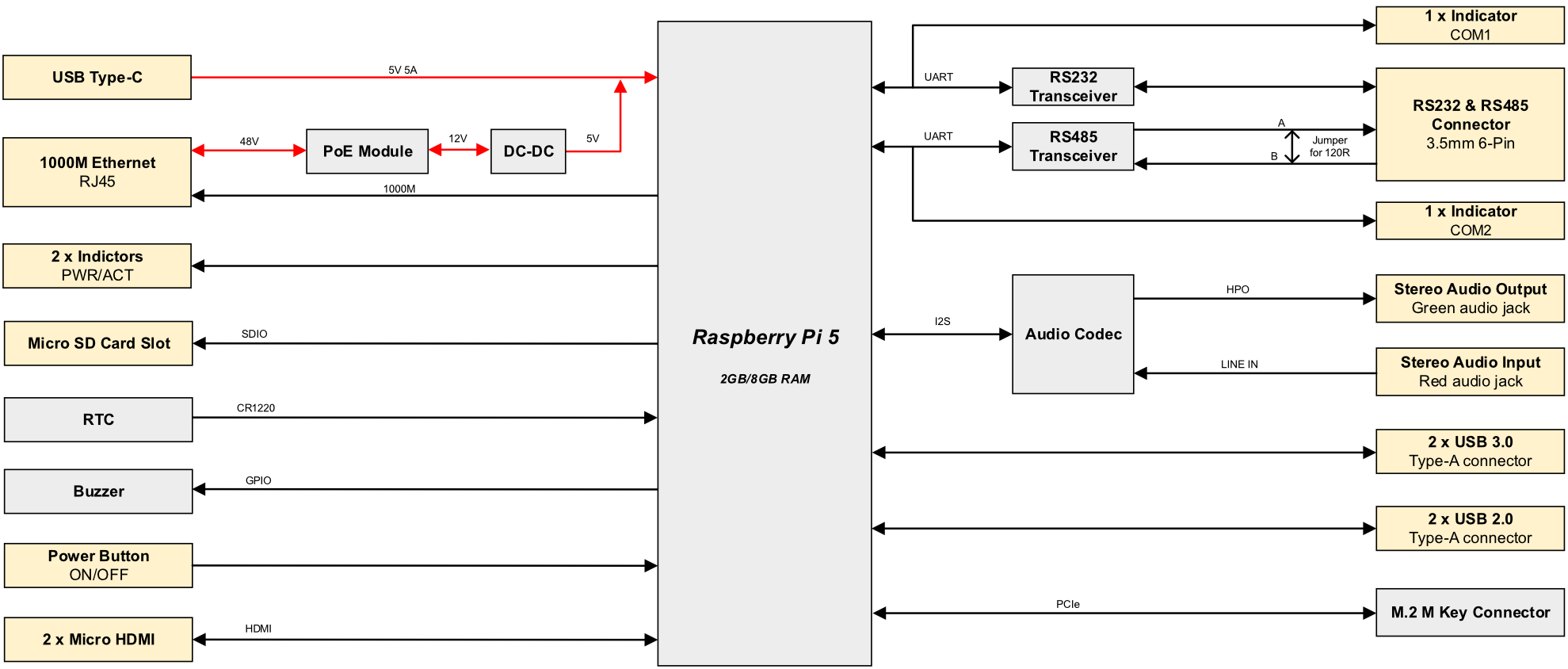

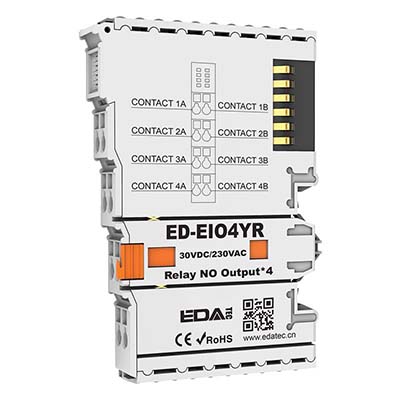

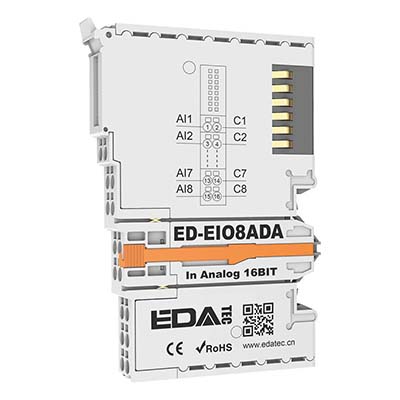

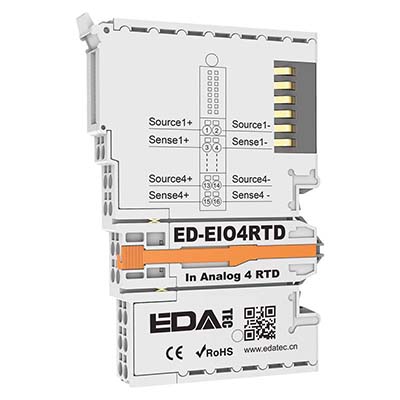

| Module | Highlights | Key Specifications/Technologies |

| Real-Time Control | Microsecond-level precision for multi-axis synchronization | - 250μs soft PLC control cycles, 16-axis motion control within 1ms - CODESYS RTE core + Web Visualization (WebVisu) |

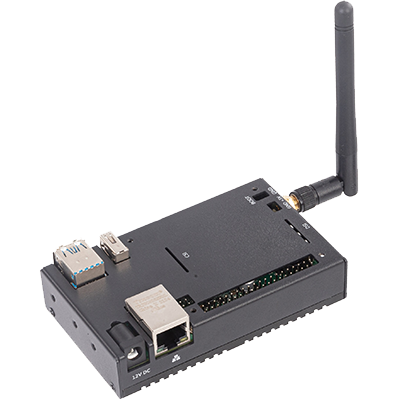

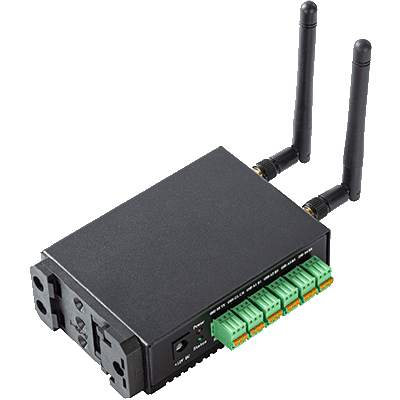

| Industrial Robustness | Reliable operation in extreme conditions | - -25°C~60°C operating range - Dual RTC backup (supercapacitor + CR1220 battery) - EMI-shielded metal enclosure |

| Protocol Integration | Unified industrial and IoT connectivity | - Native EtherCAT/Modbus TCP Master - OPC UA Server + MQTT bidirectional gateway - 2× USB 3.0 + 2× USB 2.0 |

| Scalable Architecture | Flexible storage and interface expansion | - M.2 B-Key NVMe SSD (up to 256GB) - 1× Gigabit Ethernet + 1× RS232 + 1× RS485 Phoenix terminals - Dual HDMI 4K outputs |

| Developer Productivity | Standardized programming and visualization tools | - Full IEC 61131-3 compliance (ST/LD/FBD/SFC/CFC) - CODESYS V3.5 IDE with debugging tools |

Differentiation

✅ Hard Real-Time & SoftPLC Fusion: CODESYS RTE core optimized for Raspberry Pi OS, blending ecosystem compatibility with industrial determinism.

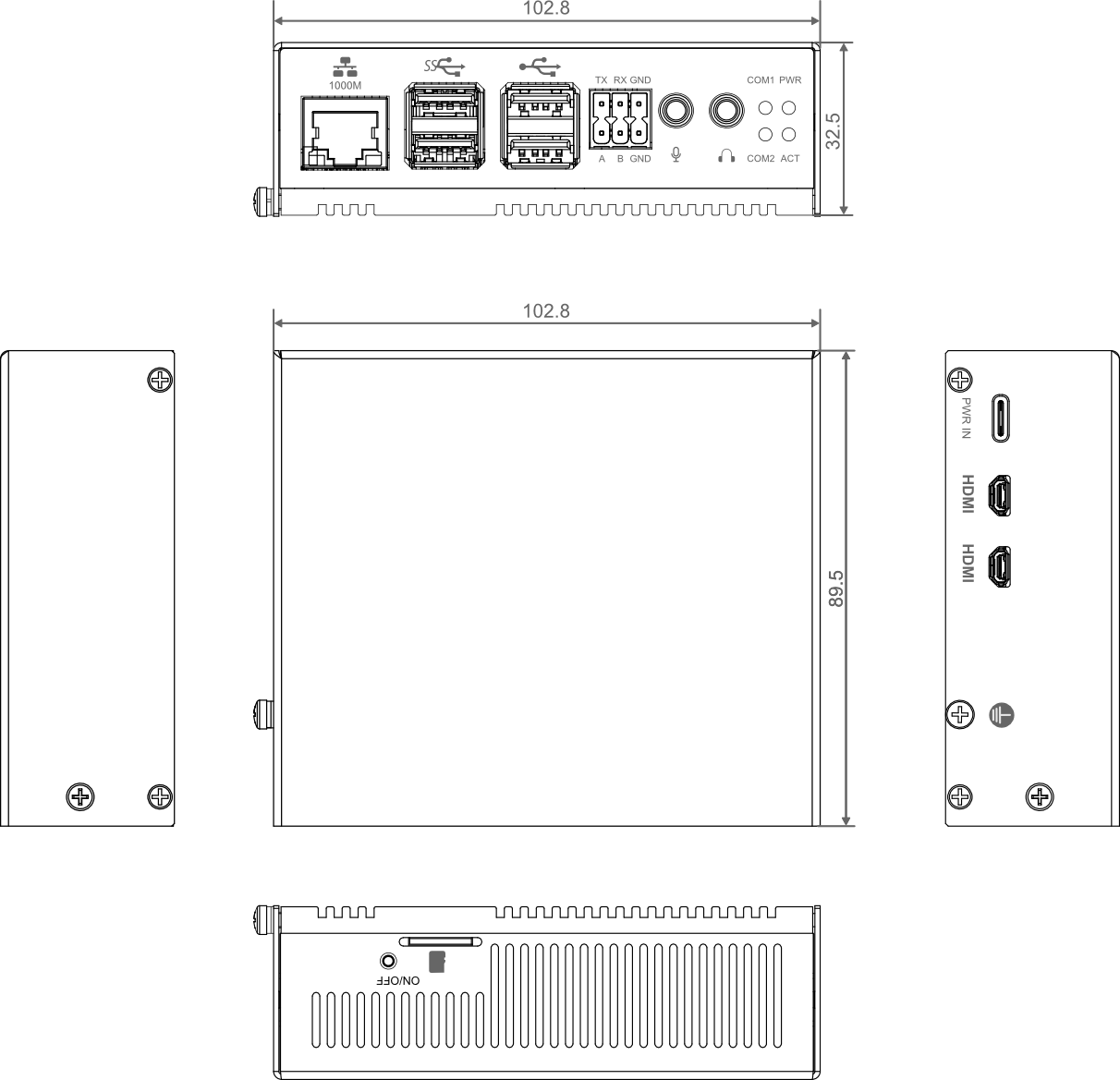

✅ Ultra-Compact Motion Controller: 102.8×89.5×32.5mm footprint enables 16-axis synchronization with <20W power consumption.

✅ Native Protocol Support: Out-of-the-box EtherCAT/Modbus TCP integration, zero-configuration deployment.

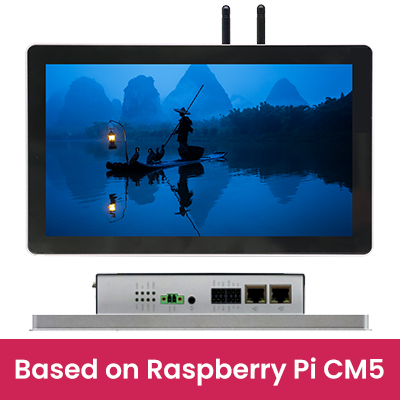

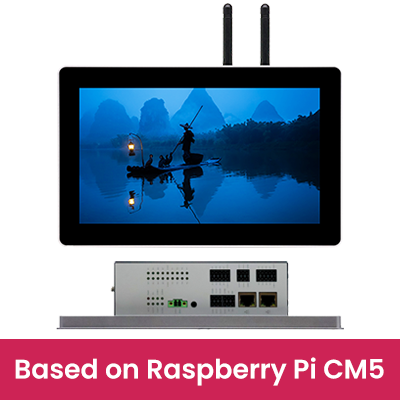

✅ Dual Visualization Modes: CODESYS WebVisu (remote HMI) + TargetVisu (local UI), simplifying human-machine interface development.

Typical Applications

🏭 Precision Motion Control: Multi-axis synchronization for semiconductor equipment, robotic arm trajectory planning.

🔌 Production Line Networking: EtherCAT-based PLC/CNC system integration, OPC UA cloud data aggregation.

📊 Edge Visualization Hub: WebVisu remote monitoring with real-time MQTT alerting.

🔋 Energy Optimization Node: Modbus TCP meter data collection, edge-based energy consumption analytics.

En

En