Best Practice Case: MES Terminal Upgrade for a Leading Manufacturing Enterprise

The Challenge

The enterprise’s existing X86 Panel PCs faced three key pain points:

1. High Costs: High hardware unit prices, plus a Windows LTSC license fee of nearly 100 US dollars per unit, with severely overprovisioned performance.

2. Bloated Systems: Windows automatic updates frequently cause production downtime, and the system is vulnerable to virus attacks.

3. Difficult Maintenance: High power consumption leads to significant heat generation; traditional fan cooling suffers frequent failures in dusty environments.

The Solution

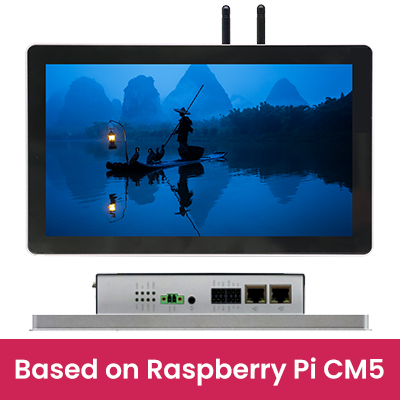

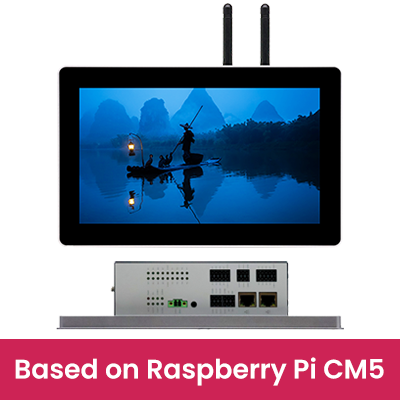

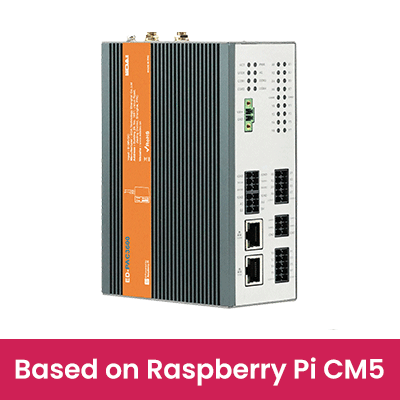

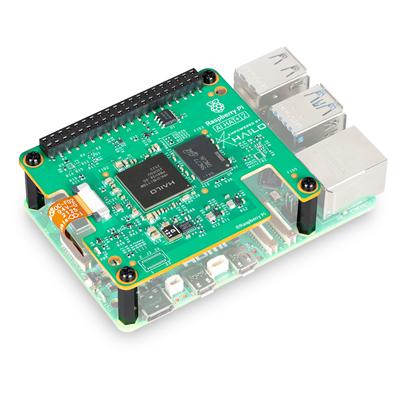

The customer adopted our 15.6" industrial-grade touchscreen HMI based on Raspberry Pi CM5: ED-HMI3630-156CA. Without changing the operational experience or mechanical structure, the customer achieved a significant reduction in system costs and complexity.

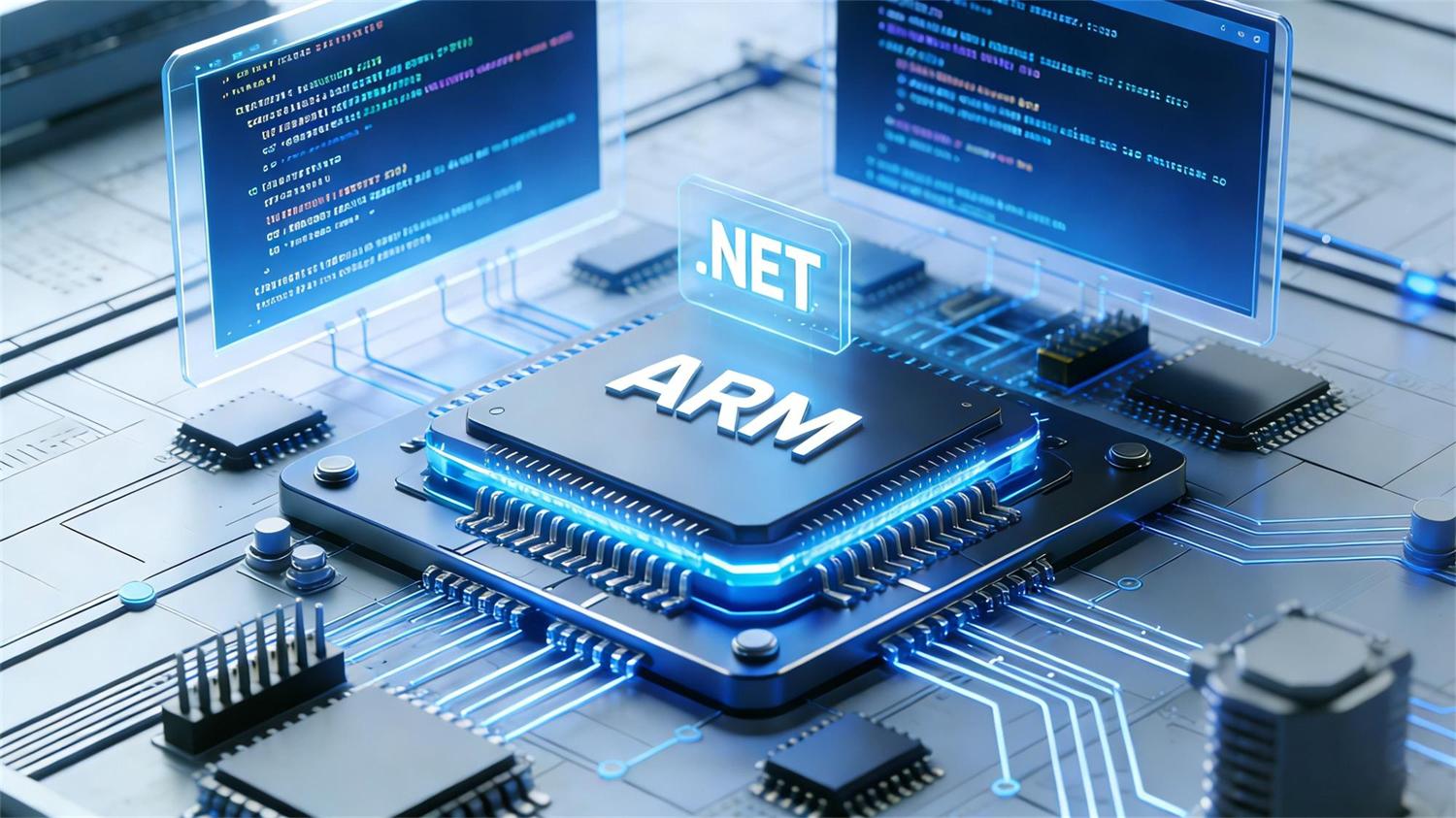

• Seamless Software Migration: Existing C#/.NET business logic is directly deployed via the .NET cross-platform framework (Avalonia), with a code reuse rate >95%.

• Industrial-Grade Ruggedization: Full aluminum alloy chassis + IP65 front panel + fanless design, physically isolating dust.

• Linux Flexibility: Adopts the completely free industrial-grade Raspberry Pi OS Lite, running only necessary HMI processes to effectively reduce system boot time.

The Result

• Hardware Costs: Total Cost of Ownership (TCO) reduced by 55%.

• Deployment Speed: Building custom OS images with rpi-imager cuts single-device deployment time from 2 hours to less than 10 minutes.

• Reliability: Stable operation for 12 months in high-dust workshops with zero failures.

Why Are Architects Choosing .NET + Raspberry Pi?

• .NET Developer-Friendly: Natively supports .NET Core, greatly lowering the migration threshold and learning costs for existing C#/VB.NET developers.

• Significant TCO Reduction: 30%-50% lower hardware costs, no operating system licensing fees, and lower power consumption for energy savings.

• Industrial-Grade Reliability: Linux systems avoid unnecessary Windows updates and security risks; the fanless design is more suitable for dusty workshops.

• Supply Chain Security: Industrial-grade Raspberry Pi Compute Modules (CM4/CM5) offer a long-term supply commitment of over 10 years.

• Long-Term Software Support: Raspberry Pi OS provides continuous, stable security updates and maintenance, eliminating worries about operating system "supply cuts"—a truly industrial-grade choice.

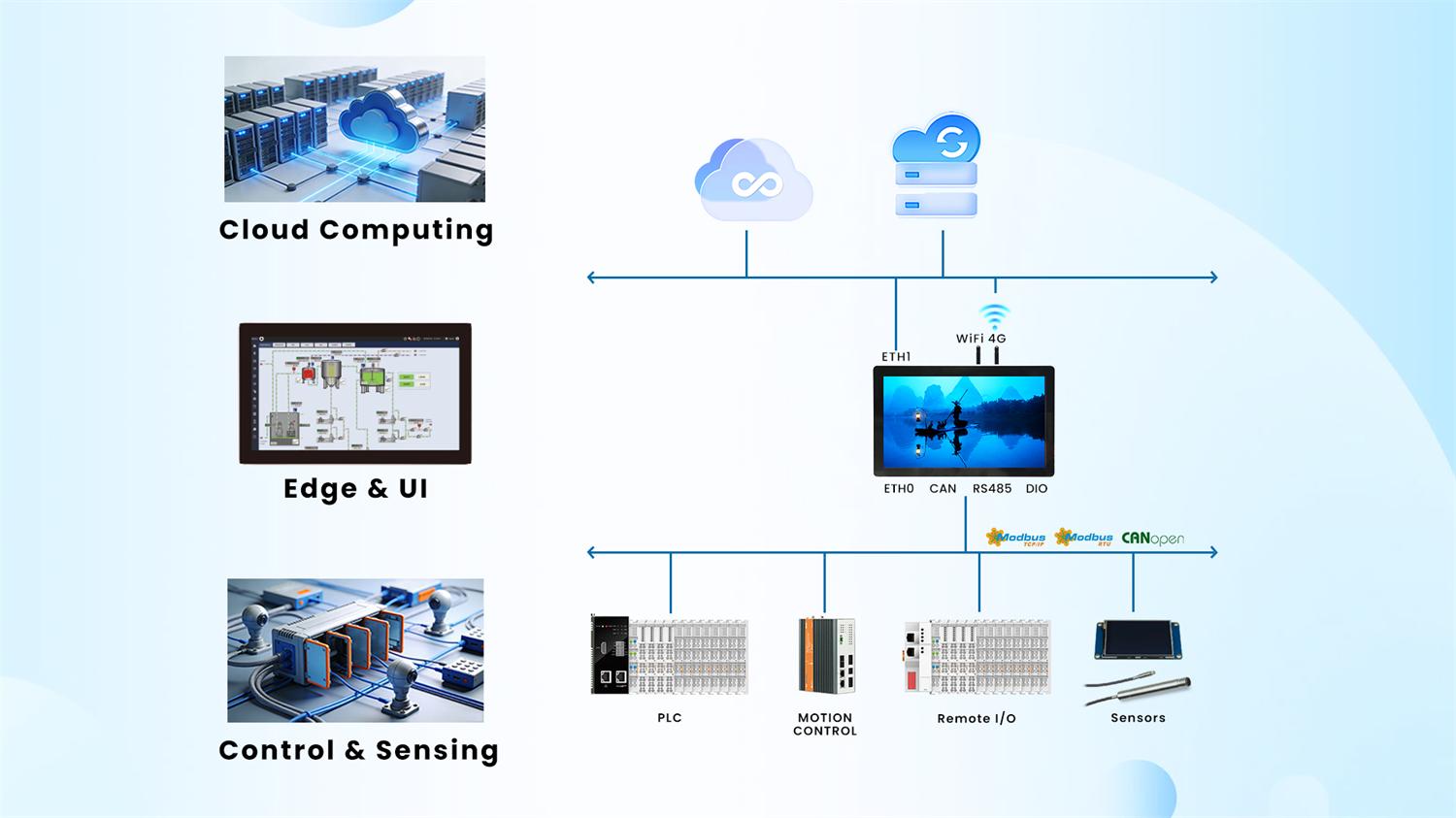

From Software Logic to On-Site Delivery: Bridging the Final Gap

Many engineers have successfully run .NET programs on Raspberry Pi development boards in laboratories, but when moving to actual industrial sites, they often get stuck at the "final step": How to make this powerful core survive in dusty, vibrating, and unstable power environments?

This is precisely the original intention behind our development of the ED-HMI3630 Raspberry Pi Industrial HMI Series.

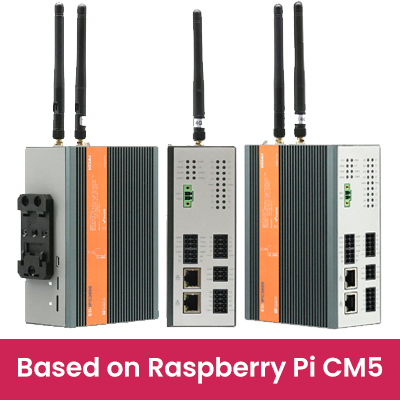

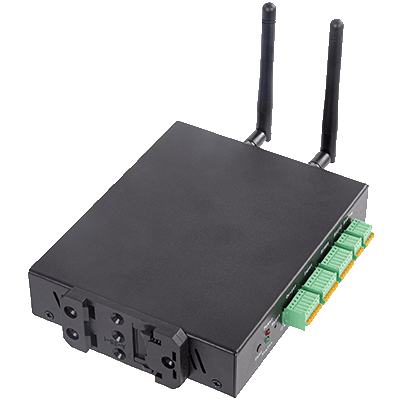

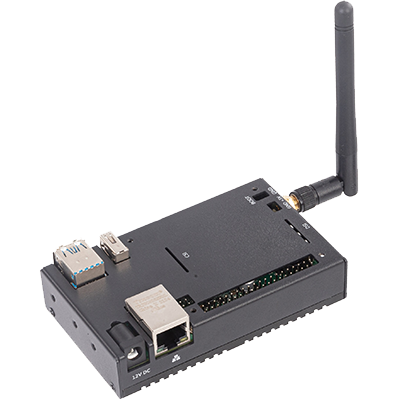

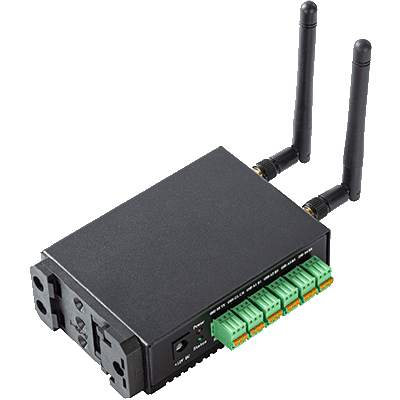

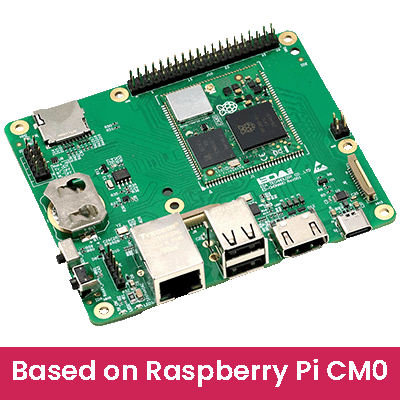

ED-HMI3630: 11.6 / 13.3 / 15.6-inch Industrial Connectivity HMI based on Raspberry Pi CM5

• 11.6 / 13.3 / 15.6" Full HD, high-brightness IPS LCD display with multi-touch support

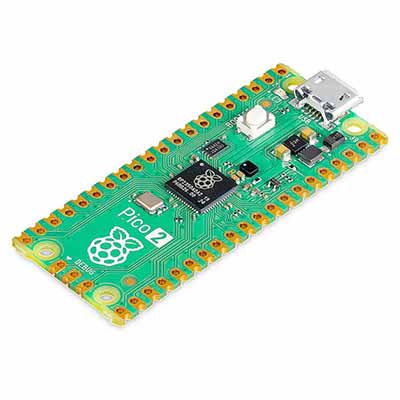

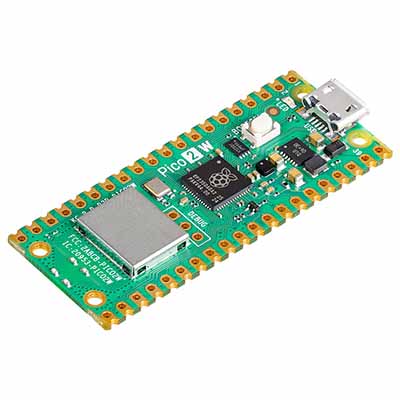

• Raspberry Pi CM5 controller: Quad-core, 64-bit Arm Cortex-A76 processor at 2.4GHz, up to 16GB memory

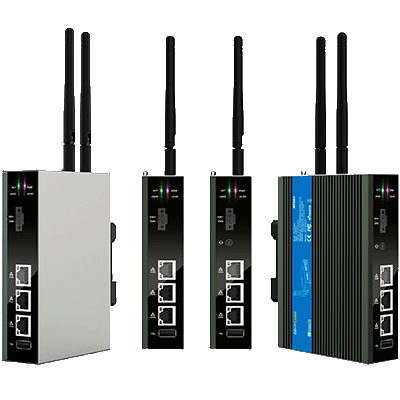

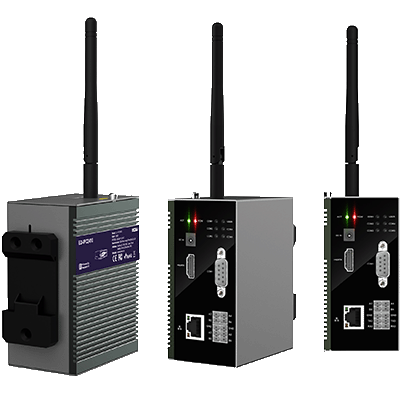

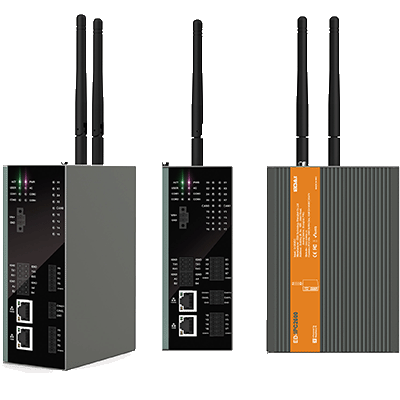

• Rich industrial interfaces and I/O, optional WiFi, BT, 4G wireless capabilities

• Aluminum alloy frame design, front panel supports IP65 waterproof rating

• Wide temperature range, wide voltage input, fanless design

ED-HMI Selection Guide

Explore the EDATEC HMI Series and refer to the Selection Guide.

En

En