RPAPlus Sdn. Bhd. is a technology enterprise headquartered in Penang, Malaysia. It focuses on the R&D and implementation of smart manufacturing and digital solutions, and is an R&D service provider certified by the Malaysian Investment Development Authority (MIDA).

Core Positioning and Qualifications

- Its core business focuses on the field of Industry 4.0, providing manufacturing industries with R&D services and customized solutions related to automation and digital transformation.

- It holds the "Pioneer Status" qualification certified by MIDA, enabling its cooperative customers to enjoy the policy preference of double tax deduction for approved R&D expenditures.

Core Capabilities and Technology Layout

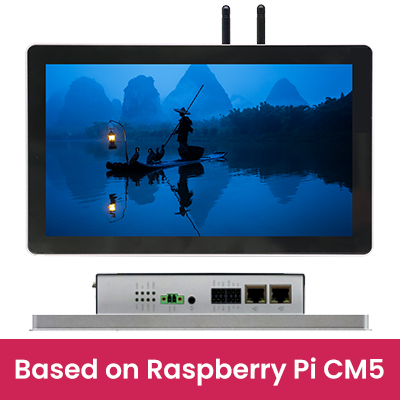

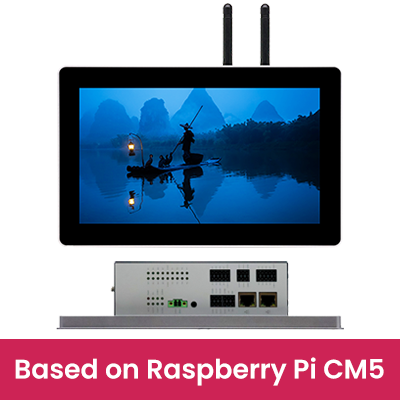

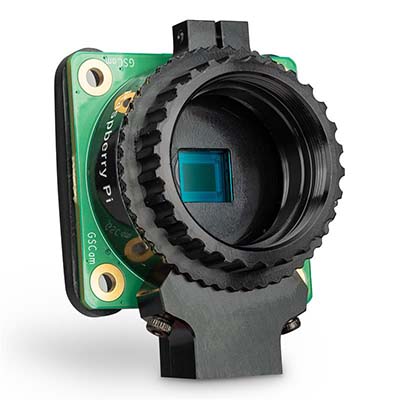

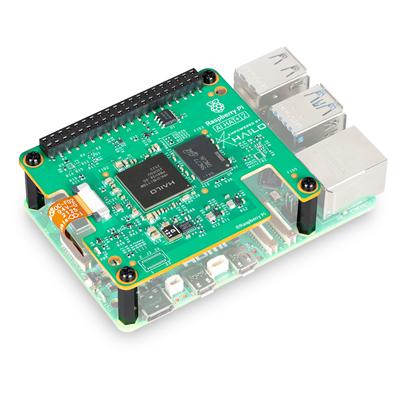

- Its technical scope covers two major sectors: automation engineering and software engineering. Core technologies include AI vision, MES system integration, robotic automation, and mobile application development.

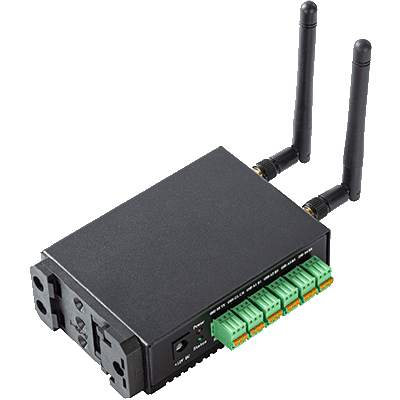

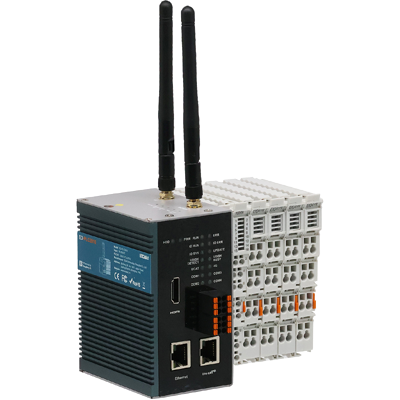

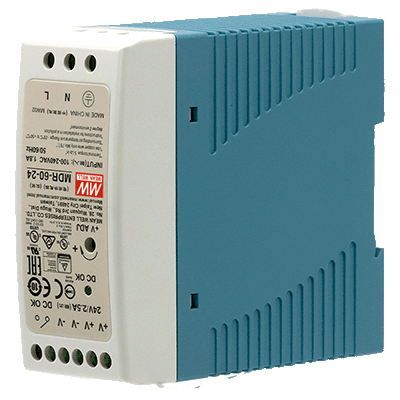

- It is compatible with various technical frameworks and hardware, with cooperative brands including BECKHOFF, KUKA, KEYENCE, etc., and supports industrial communication protocols such as EtherCAT and EtherNet/IP.

- It owns an independently developed digital Operation Management System (OMS), which can realize data connection and collaboration between OT (Operational Technology) and IT (Information Technology) fields.

Core Products and Solutions

- Smart manufacturing automation equipment: It covers scenarios such as motorcycle muffler welding and assembly, nitrile glove packaging, flat rod quality inspection, and ionized spacer removal. It provides customized solutions ranging from single-machine automation to production line integration, with core advantages of improving production efficiency and reducing labor dependence.

- Digital management systems: Including RPA-MES smart manufacturing execution system (with functions such as production planning, work order tracking, and real-time OEE monitoring), 3D SCADA control room, mobile attendance system, electronic forms, and service work order management system, which realize digital traceability and collaboration throughout the entire production process.

- Customized software services: It provides services such as exclusive software development, digital twin interaction, and ERP data synchronization, supporting cross-departmental collaboration and remote operation monitoring.

Customer and Cooperation Ecosystem

- It serves multiple sub-sectors of the manufacturing industry, with cooperative customers including enterprises and institutions such as LeaderRange, MAXIS Business, and TURCK.

- It has built a complete ecosystem covering hardware suppliers, software partners, and industry customers, and possesses full-chain service capabilities from solution design, R&D, and implementation to operation and maintenance.

En

En