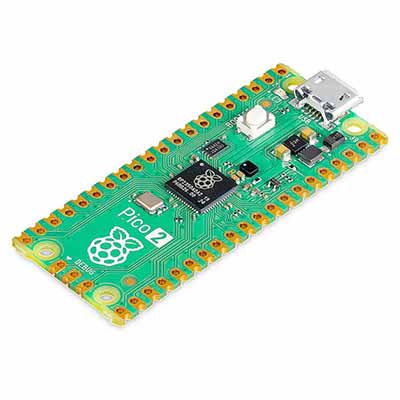

ED-AIC3000

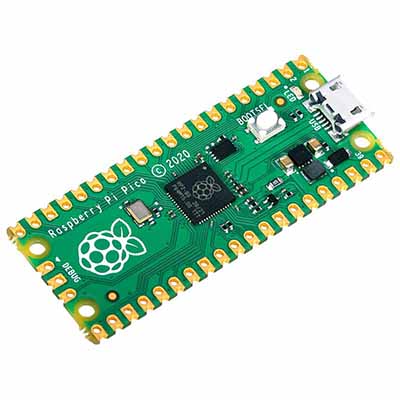

ED-SBC3300 Series

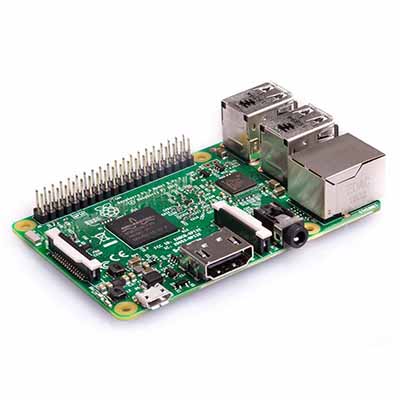

ED-IPC3100 Series

ED-IPC3600 Series

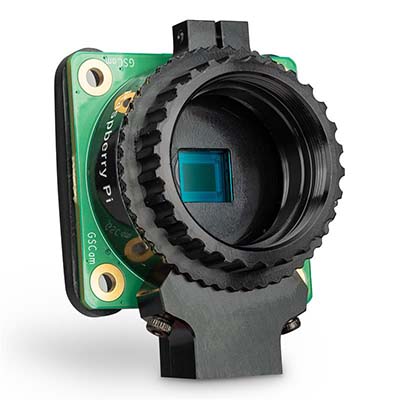

EtherCAT Coupler

ED-PLC2010

ED-AIC3000

- CM5 platform, Quad-core

- 12MP@70FPS

- 12mm Autofocus Liquid Lens

- IP65 Shockproof,0~45℃

ED-SBC3300 Series

- Mini-ITX Standard Motherboard

- CM5 platform,Quad-core

- Dual Gigabit Eth,Multiple USB,Multiple RS232&RS485

- 9V-36V input、PoE Support

ED-IPC3100 Series

- Rugged, built for industry

- CM5 platform, Quad-core

- 1 x Gigabit, 1 x 100M

- 2x RS232 & 2x RS485

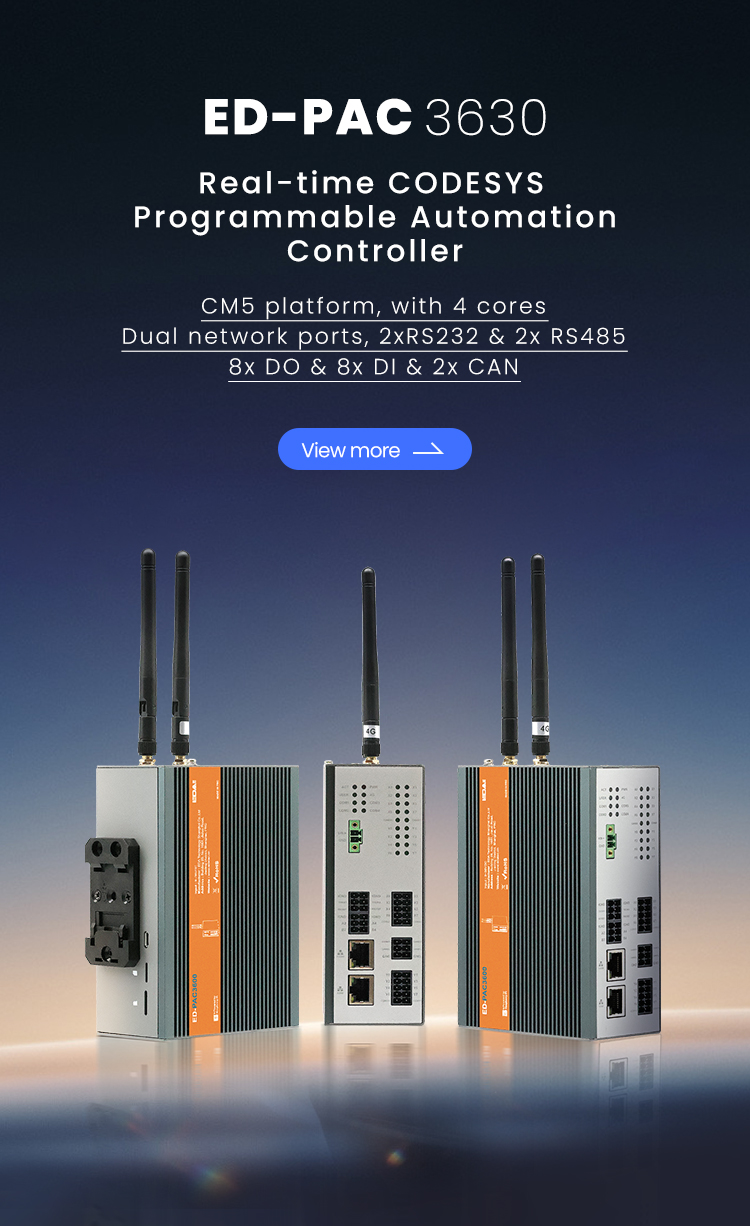

ED-IPC3600 Series

- Rugged, built for industry

- CM5 platform, Quad-core

- 1 x Gigabit, 1 x 100M

- 2x RS232 & 2x RS485

- 8x DO & 8x DI & 2x CAN

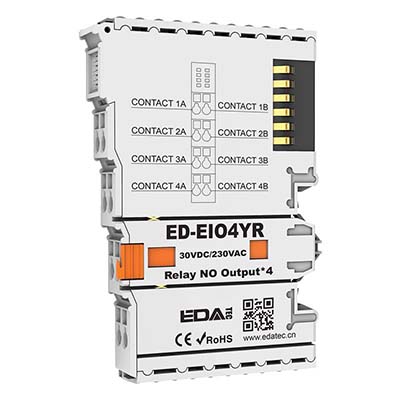

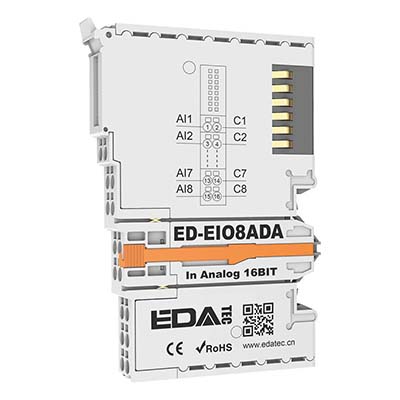

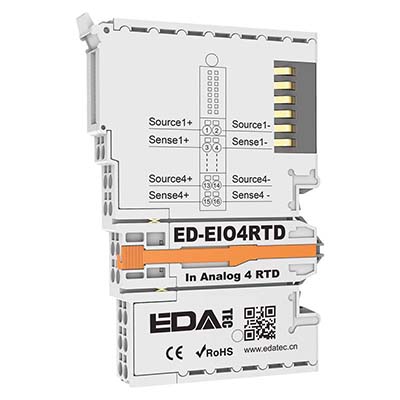

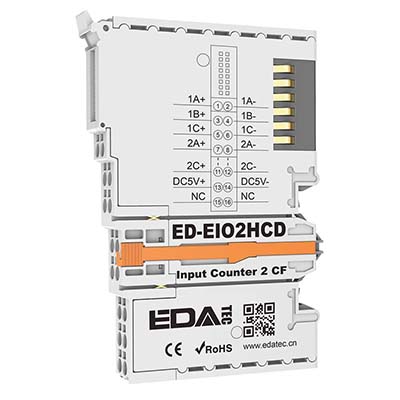

EtherCAT Coupler

- 32 I/O Module Expansion

- 65534 Couplers Cascading, 100m Inter-station

- Wide Voltage Input (DC24V±20%)

- EtherCAT Master Compatible, no IP/MAC Config

- DIN Rail Mount, IP20, CE/RoHS, -10℃~55℃

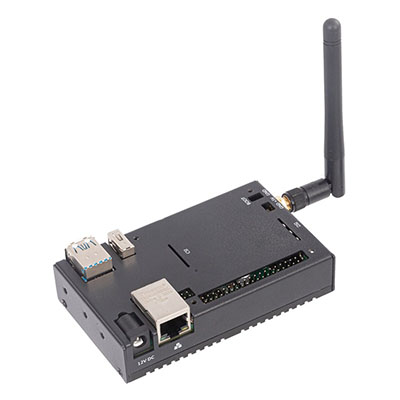

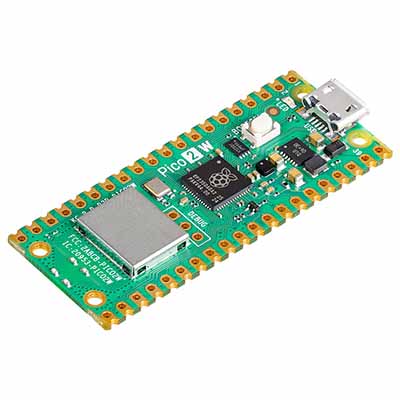

ED-PLC2010

- CM4 platform, Quad-core

- Up to 32 IO modules expansion

- Dual Eth, 2x RS232 & 2x RS485

- CODESYS-Ready/EtherCAT

En

En