-

Products

- Industrial Computers

- HMI

- PLC & PAC

- IoT Gateway

- Display

- Remote I/O

- SBC

- CPU Modules

- Cameras

- Extension Boards

- Accessories

ED-IPC2000 Series

ED-IPC2100 Series

ED-IPC2200 Series

ED-IPC2400 Series

ED-IPC2500 Series

ED-IPC2600 Series

ED-IPC3020

ED-IPC3100 Series

ED-IPC3600 Series

CM4 Industrial

CM4 IO Computer

CM4 Media

CM4 Nano

CM4 Sensing

ED-HMI2002 Series

ED-HMI2020 Series

ED-HMI2120 Series

ED-HMI2220 Series

ED-HMI2320 Series

ED-HMI2630-101C

ED-HMI3010 Series

ED-HMI3020 Series

ED-HMI3120 Series

ED-HMI3630 Series

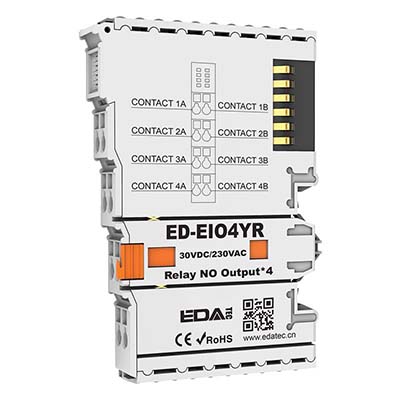

EtherCAT Coupler

EtherCAT Digital Input Modules

EtherCAT Digital Output Modules

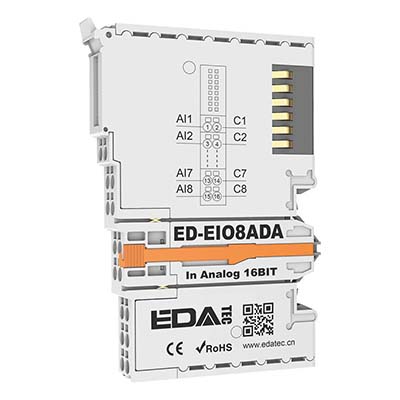

EtherCAT Analog Input Modules

EtherCAT Analog Output Modules

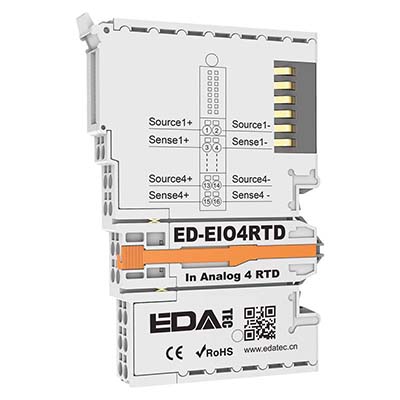

EtherCAT Temperature Input Module

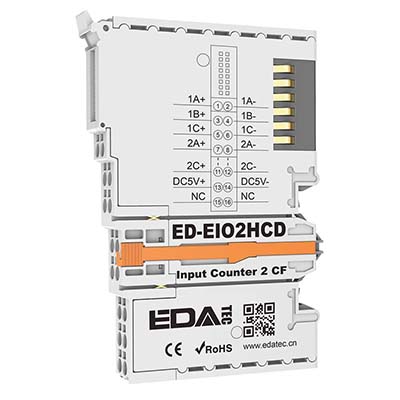

EtherCAT High-Speed Counter

Power Expansion Supply Module

Bus End Cove

ED-SBC3300 Series

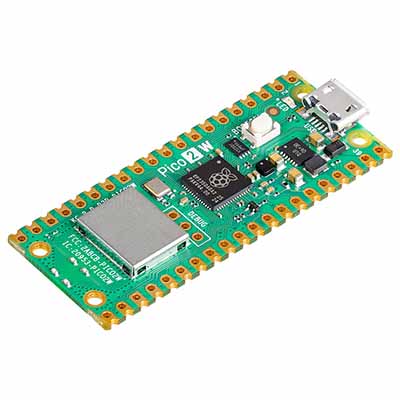

Raspberry Pi Pico 2 W

Raspberry Pi 500

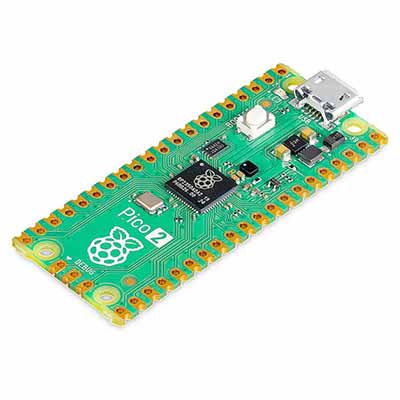

Raspberry Pi Pico 2

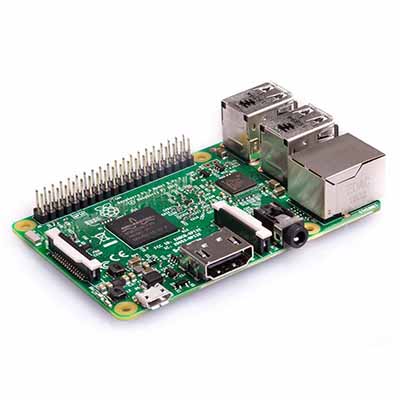

Raspberry Pi 3 Model B+

Raspberry Pi 4 Model B

Raspberry Pi 5

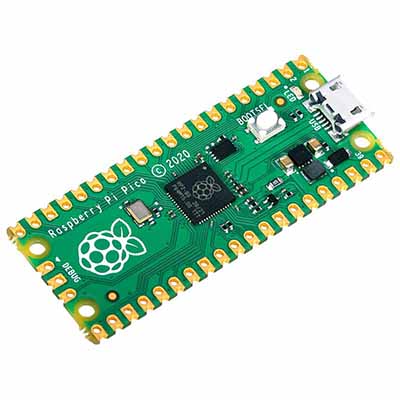

Raspberry Pi Pico

Raspberry Pi Pico W

Raspberry Pi 3 Model B

Raspberry Pi Zero

Raspberry Pi Zero W

Raspberry Pi 3 Model A+

Raspberry Pi Zero 2 W

ED-SBC2300

REIMEI1

Raspberry Pi Compute Module 5

Raspberry Pi CM3+

Raspberry Pi CM4

Raspberry Pi CM3

Compute Module IO Board V3

Compute Module Development Kit

ED-AIC3100

ED-AIC3000

CM4 AI Camera

M12 Fisheye Lens

M12 Fixed Lens

Raspberry Pi AI Camera

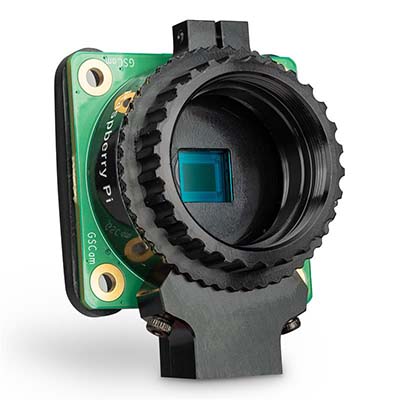

Raspberry Pi Camera Module 3

Raspberry Pi Camera Module 2

Raspberry Pi High Quality Camera

Raspberry Pi Global Shutter Camera

16mm/10MP Lens for HQ Camera

6mm/3MP Lens for HQ Camera

Raspberry Pi CM5 IO Board

CM5 Development Kit

Raspberry Pi PoE+ Injector

40pin I/O Protector

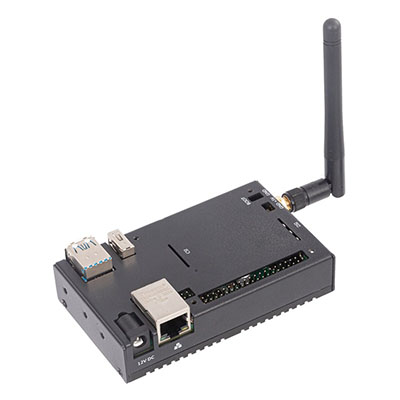

ED-GW1302S LoRaWAN

ED-GW1303S LoRaWAN

Raspberry Pi SSD Kits for Pi 5

Raspberry Pi AI HAT+

Raspberry Pi M.2 HAT+

Raspberry Pi AI Kit

MIPI Cable Extension

Raspberry Pi Cooler for CM5

Raspberry Pi CM5 IO Case

Raspberry Pi CM5 Active Cooler

ED-Pi5Case-EXT

Raspberry Pi 45W USB-C Power Supply

ED-ACCBKT-L3020

ED-ACC-ANT-G4G25-L10/L20

Raspberry Pi SD Cards

Raspberry Pi Bumper for Pi 5

ED-Pi4Case-OB

Raspberry Pi 15W Power Supply

ED-Pi5Case-HA

ED-ACCHMI-Front

ED-Pi5PCOOLER

ED-Pi4PCOOLER

40pin IO Extender

CM4 Cooler

2.4GHz/5.8GHz Antenna kit for CM4

CM4 IO Smart Case

ED-Pi5Case-B

ED-Pi5Case-O

ED-PSU1201

ED-PSU1202

- Solutions

- Custom Design

- Docs

- Support

- Company

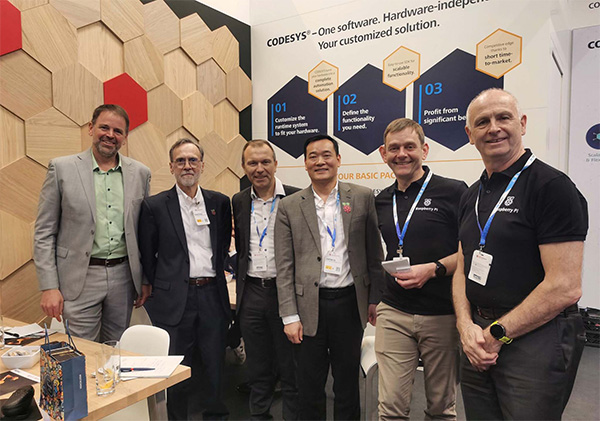

- Partners

- Old Web

En

En